Chinese (Simplified)

English

German

Korean

Spanish

When you're ordering a machined part, you might think "more precision is always better." But here's the thing – that's actually costing you money unnecessarily. At Ruo Chen, we work with tolerances every single day, and I can tell you that understanding what precision your part actually needs is one of the best decisions you'll make for your bottom line.

Before we dive deep, let's get straight to the point. The level of precision your part needs depends on three main factors:

Most manufacturers over-specify tolerances by 50-100%, which means they're paying for precision they don't need. At Ruo Chen, we help clients identify the sweet spot – getting exactly the precision required, no more, no less.

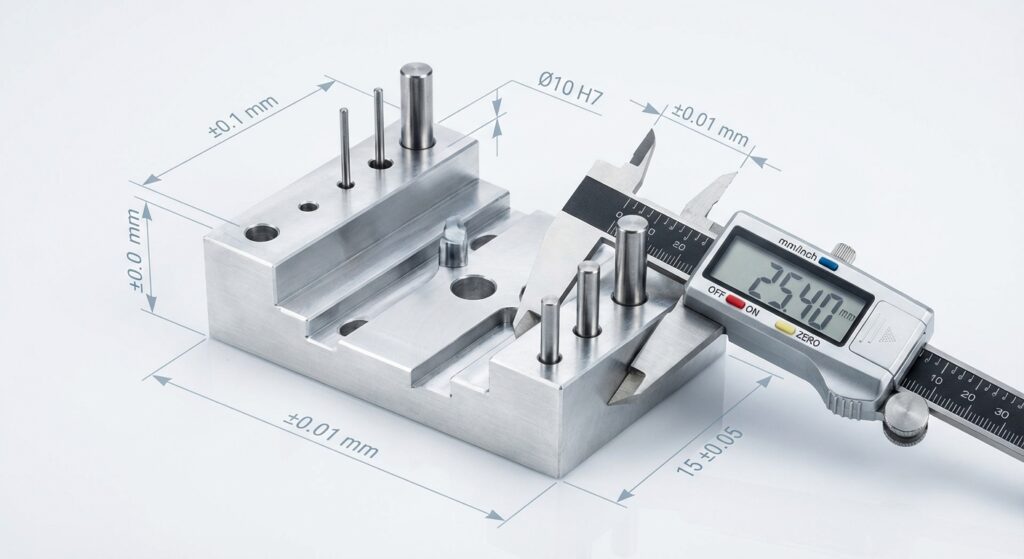

Let me break this down simply. A tolerance is the acceptable range of variation in a dimension. For example, if you specify a hole at 10mm ± 0.05mm, you're saying that hole can be anywhere from 9.95mm to 10.05mm, and you'll accept it.

Sounds straightforward, right? But here's where it gets interesting.

Tighter tolerances = higher costs. It's not linear either. Going from ± 0.5mm to ± 0.1mm might double your price. Going from ± 0.1mm to ± 0.01mm could triple it. Why? Because tighter tolerances require:

So if you're specifying ± 0.01mm when your application only needs ± 0.5mm, you're literally throwing money away.

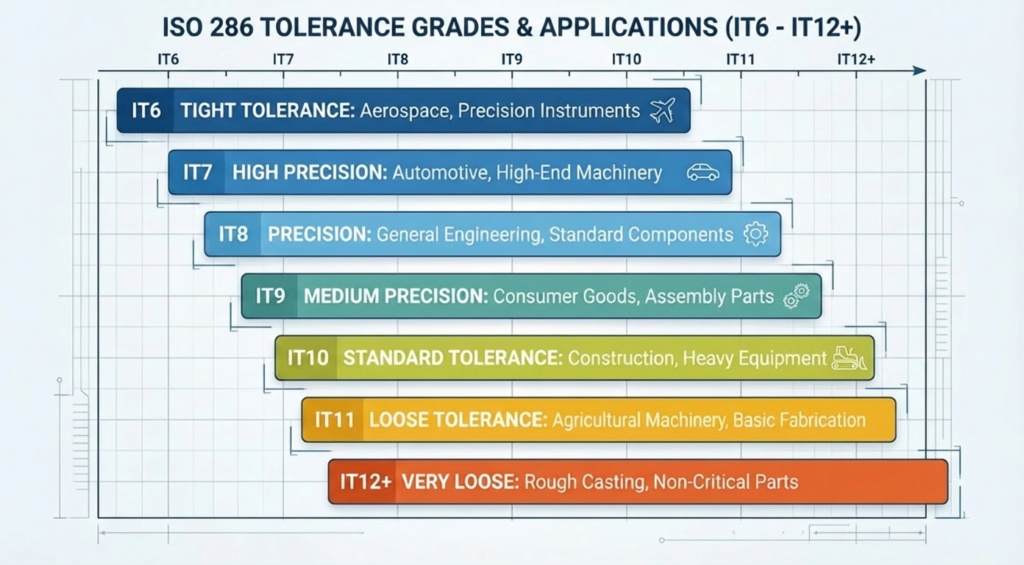

The international standard for tolerances is ISO 286. This system uses grades (IT) to define how tight a tolerance is. Let me explain the common ones we use at Ruo Chen:

Most parts fall into IT8-IT10 range. That's your sweet spot for cost-effectiveness.

Here's a practical example: a standard shaft for industrial equipment might be specified as IT7 (tight), costing 28. That's a 38% savings for dimensions that function identically in most applications.

Let me tell you a story from our shop. A client came to us with a batch of 500 aluminum brackets. Their engineer had specified tolerances of ± 0.05mm across all dimensions. It was an internal bracket – nobody would ever see it, and it just needed to fit in a larger assembly.

We quoted $8,500 for the job. The client was shocked at the price. Then we asked a simple question: "Do you actually need ± 0.05mm precision?"

After a quick call with their engineering team, they realized the answer was no. They revised the tolerances to ± 0.2mm where it didn't matter, keeping tight tolerances (± 0.05mm) only on two critical dimensions that affected fit.

New quote: $3,200. That's a 62% reduction.

The bracket worked perfectly. It still does, and we've been making them that way for two years.

This scenario plays out constantly. Most over-specification comes from:

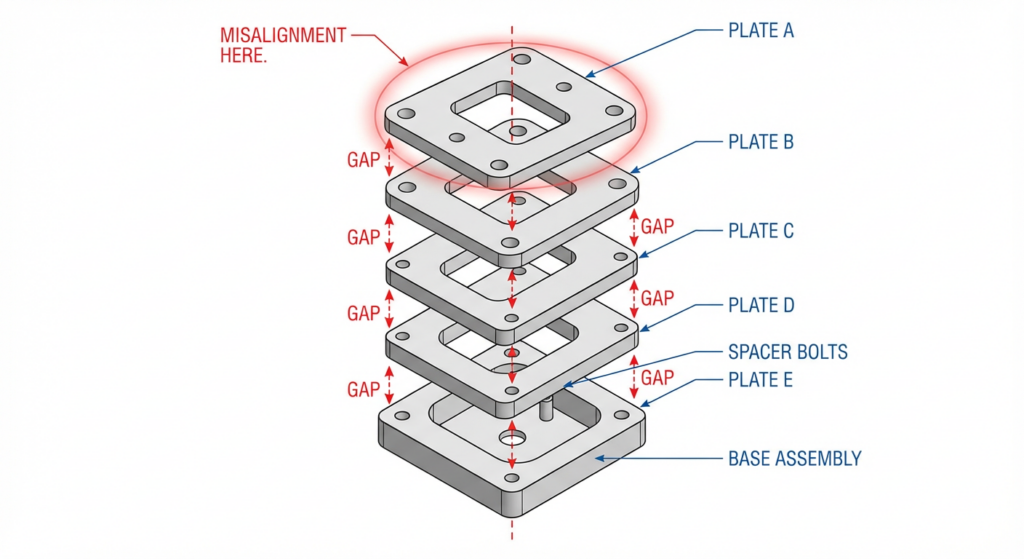

Here's something many engineers forget: tolerances add up. This is called tolerance stack-up, and it's crucial for assemblies with multiple parts.

Imagine you're building an assembly with 5 stacked parts, each with a thickness tolerance of ± 0.1mm. Theoretically, your stack could be:

That's a potential 0.9mm variation in total stack height – maybe too much for your application.

When we design parts at Ruo Chen, we use tolerance stack-up analysis to ensure assemblies work. Sometimes this means tightening tolerances on certain parts while loosening others. It's a balancing act.

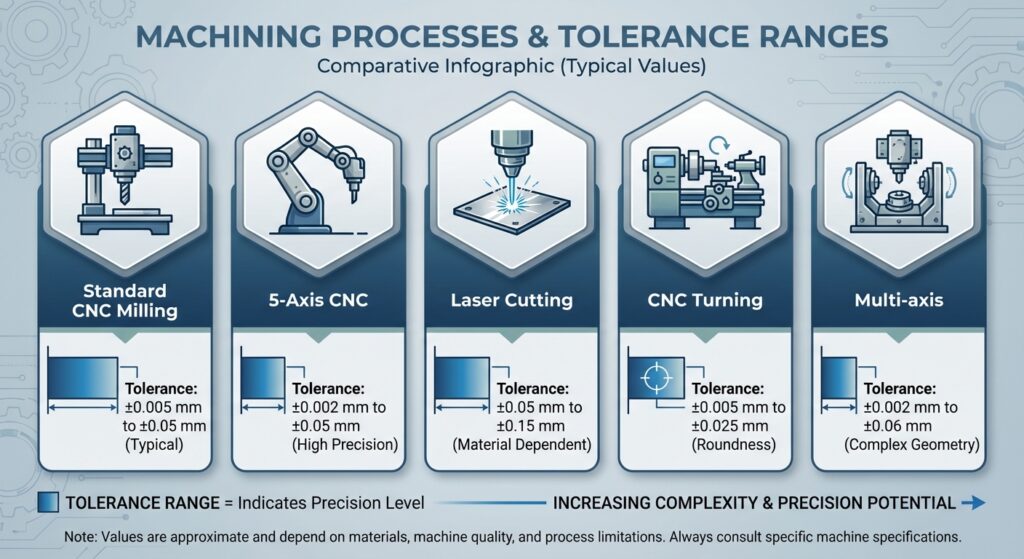

Not all machines are created equal. Here's what we can typically achieve with our equipment at Ruo Chen:

Standard CNC Milling: ± 0.05mm (good for general parts)

5-Axis CNC: ± 0.03mm (complex geometries with tight tolerance)

Laser Cutting: ± 0.1mm (depends heavily on material thickness)

CNC Turning: ± 0.02mm (cylindrical parts, excellent repeatability)

Multi-axis Machining: ± 0.01mm (when precision is critical)

The tighter the tolerance you need, the more specialized equipment and expertise you require. That's why it costs more.

Based on our experience at Ruo Chen, here's how to think about tolerance specification:

For prototype or one-off parts: Be realistic about what you need. Most one-offs work fine with standard tolerances (± 0.1-0.2mm). You can always make adjustments.

For production runs (10-1000 units): This is where cost savings matter most. Specify tight tolerances only where they're functionally necessary.

For high-volume production (1000+ units): Invest in tighter tolerances on critical dimensions. The per-unit cost is lower, and quality is more consistent.

For assemblies: Always do stack-up analysis. Over-tightening all tolerances is expensive and often unnecessary.

For wear surfaces: Consider slightly tighter tolerances. A bearing journal, for example, really does need precision.

For non-critical dimensions: Let them be loose. A cosmetic surface doesn't need ± 0.05mm.

This is important: your machining supplier should be helping you optimize tolerances, not just accepting whatever you specify.

At Ruo Chen, we have conversations with clients about:

A good machine shop understands your application. We know that sometimes a ± 0.5mm tolerance makes perfect sense, and other times you genuinely need ± 0.01mm.

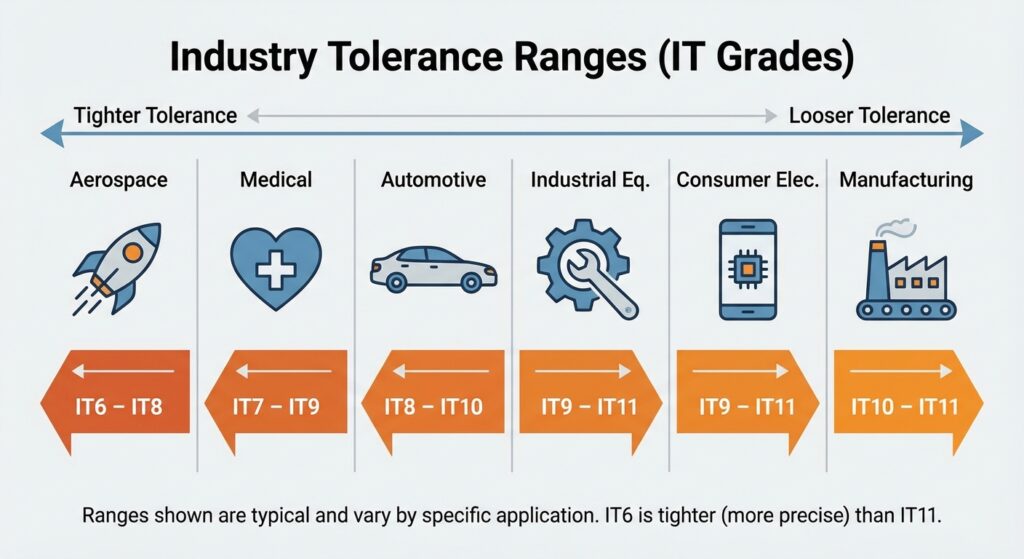

Different industries have different requirements:

Aerospace & Medical: Typically IT6-IT7, very tight, no compromise. Precision is safety.

Automotive: Usually IT8–IT9, following industry standards, well-controlled but not extreme.

Industrial Equipment: IT9-IT10, functional fit is what matters. Often looser than designers specify.

Consumer Electronics: Varies widely. Some components are IT6, others are IT11.

General Manufacturing: IT10-IT11, cost-conscious, function is primary concern.

Knowing your industry baseline helps prevent both under and over-specification.

Understanding tolerances is about being smart with your manufacturing budget. Precision costs money. More precision costs exponentially more money. And in most cases, you don't need as much precision as you think.

At Ruo Chen, we've spent years mastering different machining processes – from standard CNC milling to complex 5-axis work, laser cutting, turning, and everything in between. We can achieve whatever tolerance your part actually needs. But we also know when we can help you save 30-50% by right-sizing those tolerances.

Start asking yourself: "What does this part really need to do?" Then talk to your machining partner about what precision level that actually requires. You might be surprised at how much you can save without compromising function.

That's smart manufacturing.