Chinese (Simplified)

English

German

Korean

Spanish

If you're in the aerospace industry, you already know that precision isn't just a buzzword—it's a requirement. Every component that goes into an aircraft or spacecraft has to meet exacting standards, and that's exactly why aerospace companies have made multi-axis machining their go-to manufacturing solution. In this article, I'll walk you through the reasons why this technology has become absolutely critical to modern aerospace manufacturing.

Let me cut straight to the chase. Aerospace components demand precision tolerances that conventional machining simply can't deliver reliably. Multi-axis machining—particularly 5-axis systems—allows manufacturers to complete complex parts in a single setup, reducing errors, cutting production time, and ultimately delivering the quality that keeps aircraft flying safely.

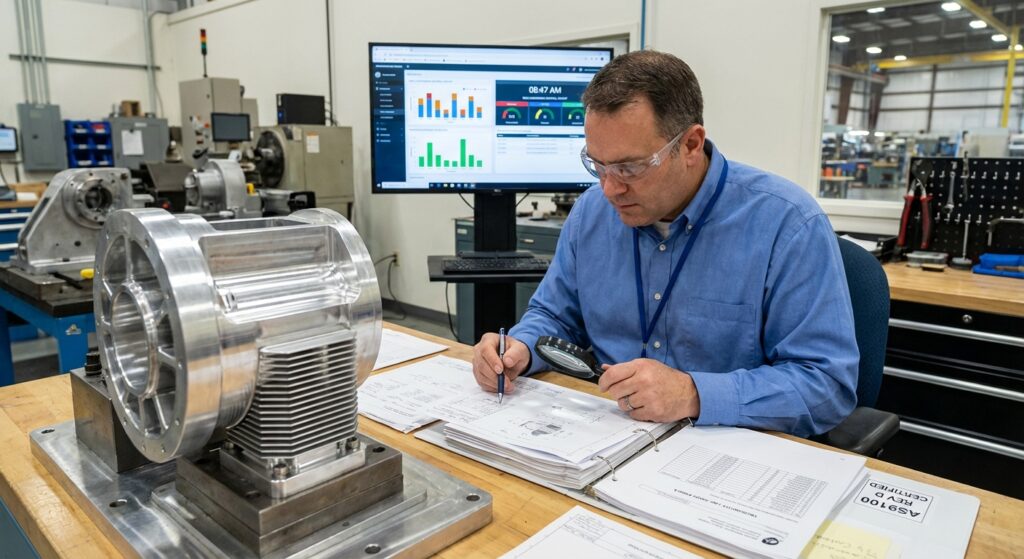

To achieve this level of precision, our facility relies on advanced 5-axis CNC milling equipment designed specifically for aerospace-grade components.

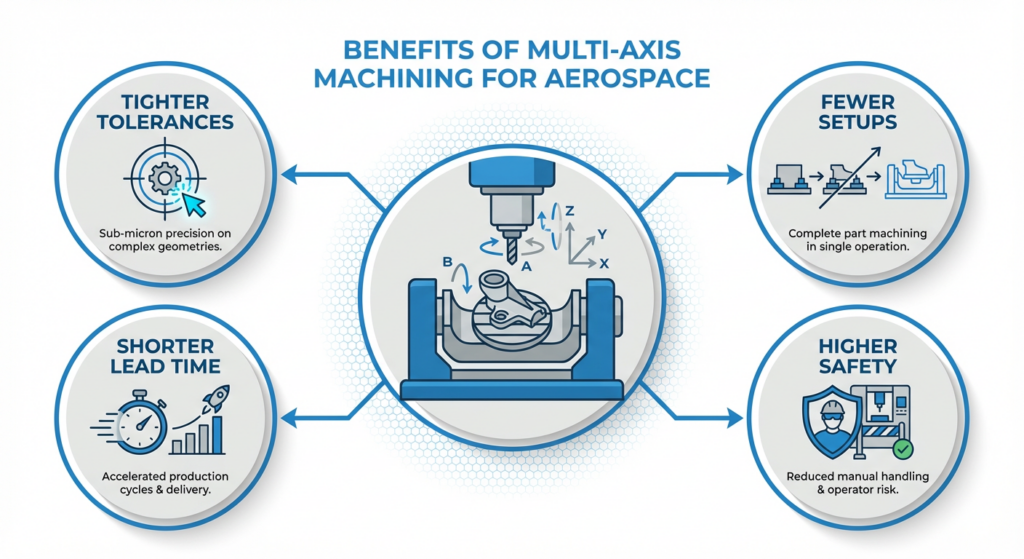

The aerospace industry doesn't compromise on quality. When you're dealing with aircraft structural components, landing gear, turbine blades, or engine housings, a small mistake can have catastrophic consequences. Multi-axis machining eliminates most of these risks by enabling simultaneous machining from multiple angles, which means fewer setups, less handling, and most importantly, tighter tolerances.

Here's the real kicker: companies that invest in multi-axis machining capabilities gain a serious competitive advantage. They can produce parts faster, more accurately, and more cost-effectively than competitors still relying on traditional 3-axis machines. For aerospace suppliers like us at Ruo Chen, offering multi-axis solutions has become non-negotiable.

These advantages are essential in aerospace programs that require consistent, repeatable mass production of critical components.

Before we dive deeper, let's make sure we're on the same page about what multi-axis machining actually is.

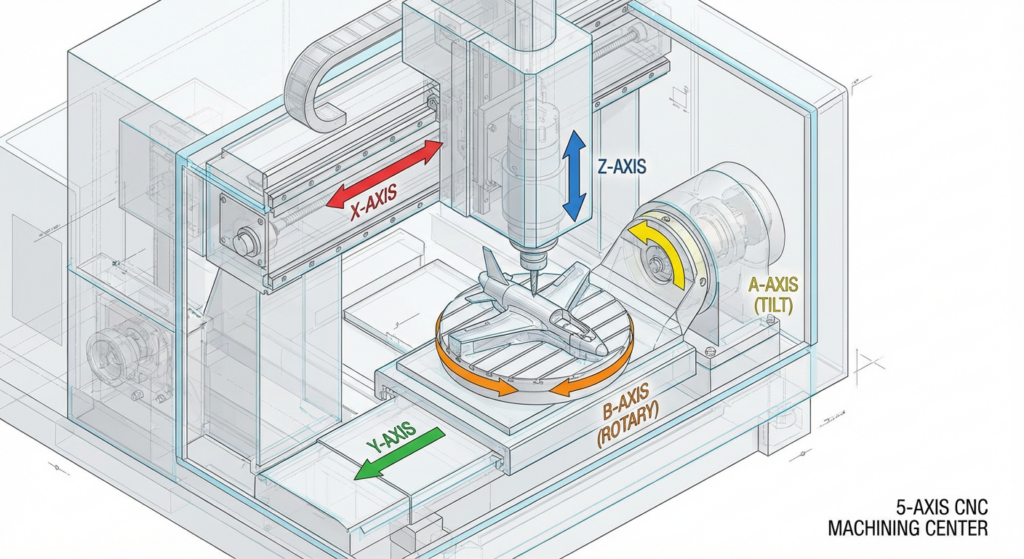

Multi-axis machining refers to CNC machines that can move a cutting tool (or the workpiece) simultaneously along more than three axes. While traditional machines operate on X, Y, and Z axes, multi-axis systems add rotational axes—typically A, B, and C—allowing the tool to approach the workpiece from virtually any angle.

A 5-axis machine is the most common configuration in aerospace. It combines three linear axes (X, Y, Z) with two rotational axes, enabling the cutting tool to machine all sides of a part without repositioning the workpiece. Some advanced shops use 7-axis or even higher configurations for exceptionally complex geometries.

When you machine a part using multiple axes simultaneously, you're not just changing the angle of approach—you're maintaining optimal tool angles and feed rates throughout the entire operation. This consistency translates directly into superior surface finishes and dimensional accuracy. For aerospace components, we're talking about tolerances in the range of ±0.005 inches or better, sometimes even tighter for critical features.

Let's talk specifics about what makes aerospace manufacturing so demanding.

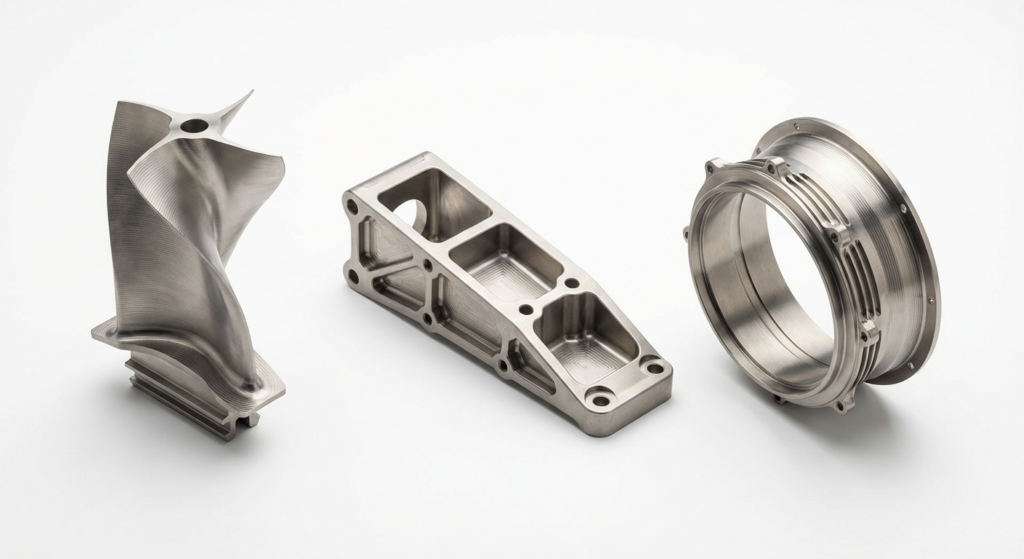

Aerospace components aren't simple boxes or cylinders. Modern aircraft are marvels of engineering with aerodynamic designs, intricate internal passages, and curved surfaces that optimize performance and reduce weight. A single turbine blade might have 3D curves that must be machined to near-perfect precision. Try doing that on a 3-axis machine and you'll quickly understand why aerospace manufacturers have moved to multi-axis systems.

Consider an engine housing with internal cooling channels, mounting bosses on multiple faces, and precision bearing surfaces. On a traditional machine, you'd need multiple setups—one for the top, one for the sides, one for the bottom. Each setup introduces the possibility of errors. Each time you touch the part, you risk damaging the finished surface or introducing dimensional inconsistencies. With 5-axis machining, you can program the entire part and run it in a single operation.

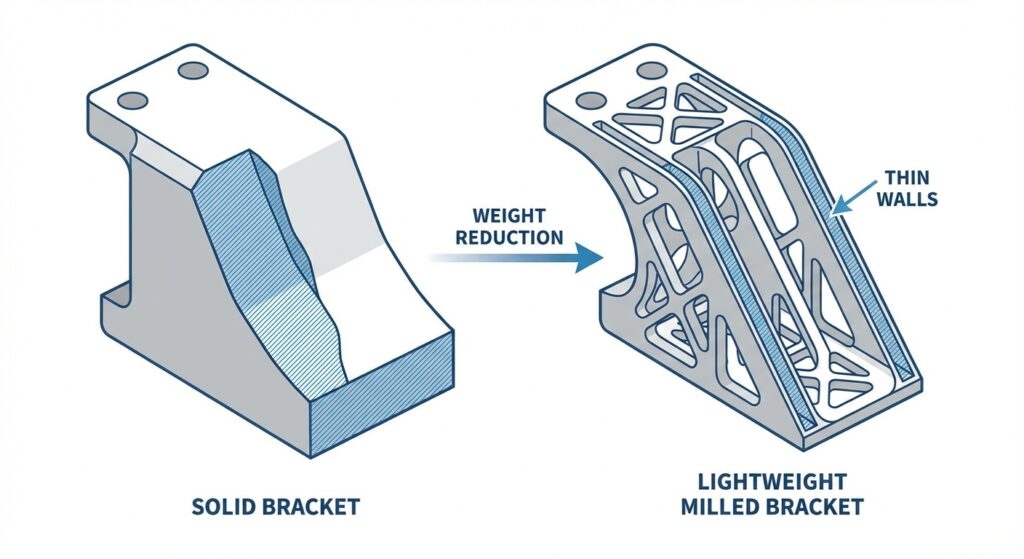

Modern aerospace is obsessed with weight reduction, and for good reason. Every pound you save on an aircraft is a pound less fuel it needs to burn, which means lower operating costs and reduced emissions. This has led to the development of components with complex internal structures—hollow sections, thin walls, and strategic reinforcement ribs.

These lightweight designs are essentially impossible to manufacture efficiently with conventional machining. Multi-axis machines can access internal features that 3-axis machines simply cannot reach without extensive fixturing or multiple operations. We're talking about interior channels, pockets at unusual angles, and precisely positioned holes that serve specific structural or aerodynamic purposes.

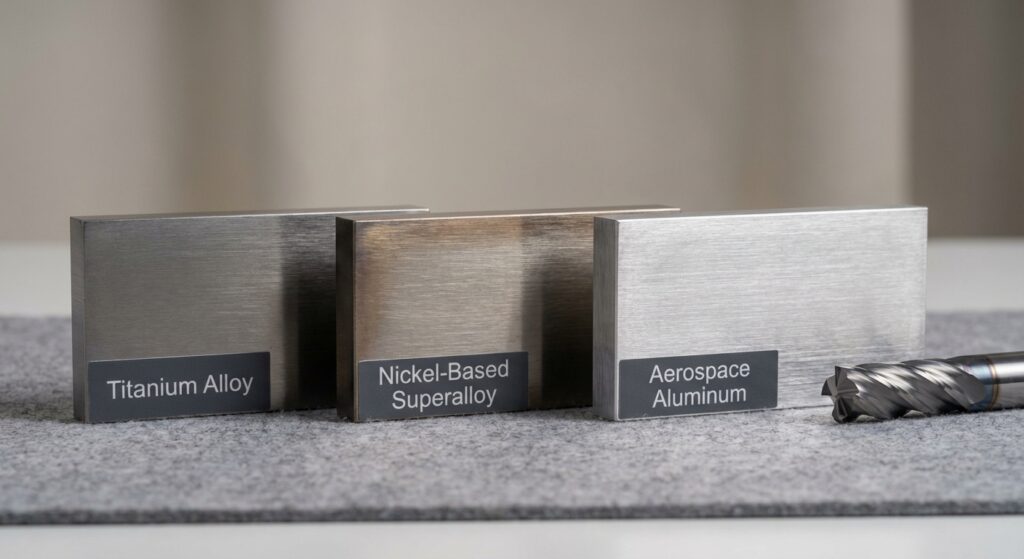

Aerospace components are typically made from materials that are notoriously difficult to machine: titanium alloys, nickel-based superalloys, and advanced aluminum alloys. These materials generate intense heat, require specific cutting speeds and feeds, and demand tools with excellent hardness and toughness.

Multi-axis machining handles these challenges better because it allows for optimal tool angles and engagement. The machine can approach the workpiece from the angle that provides the best cutting conditions, rather than forcing a compromise angle to fit a simpler machine's limitations. The result is faster cutting speeds, longer tool life, and better surface finish—all critical when working with expensive aerospace materials.

The aerospace industry operates under strict regulatory frameworks—FAA, EASA, AS9100, and others. These standards require documented traceability, proven manufacturing processes, and consistent quality outputs. Multi-axis machines, equipped with modern CNC controls and monitoring systems, generate detailed records of every operation.

When you can produce parts with tighter tolerances and greater consistency, certification becomes easier. Inspection requirements decrease because the statistical likelihood of out-of-spec parts is minimized. From a compliance standpoint, multi-axis machining is actually the smart move.

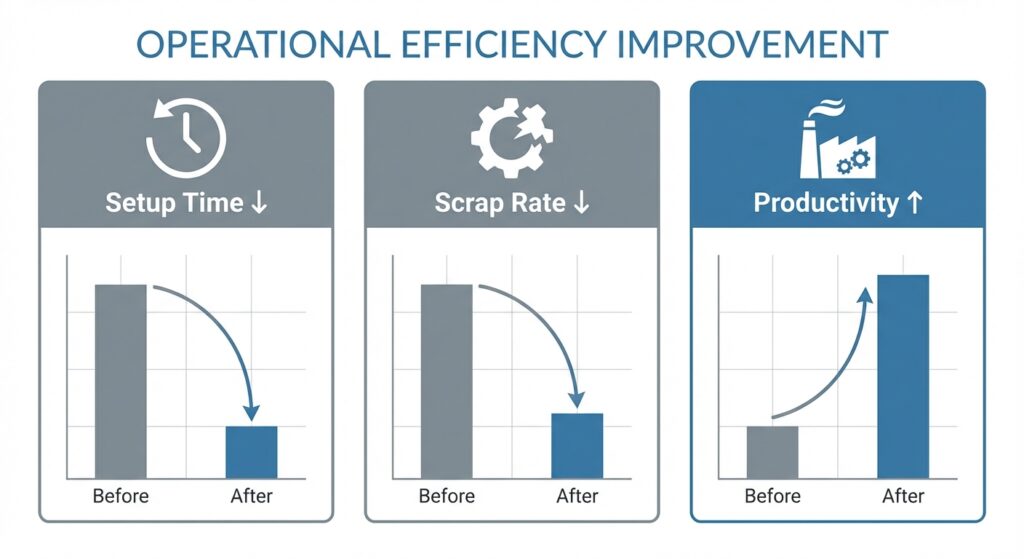

Multi-axis machining isn’t just about precision—it also helps aerospace manufacturers reduce cost by streamlining production, lowering scrap rates, and eliminating unnecessary setups.

Remember what I mentioned about needing multiple setups on conventional machines? Each setup requires:

Multi-axis machines consolidate this into a single setup. We've seen projects where switching to 5-axis machining cut production time by 40-60% simply by eliminating intermediate steps. That's direct labor savings that impact your bottom line immediately.

Manufacturing defects are expensive in aerospace. A part that's out of tolerance doesn't just get tossed—it requires inspection, documentation, investigation, and often rework or replacement. With the consistency that multi-axis machining provides, scrap rates typically drop significantly.

I've worked with aerospace suppliers who reduced scrap by 5-10% just by moving to multi-axis equipment. When you're running millions of dollars of annual production, that's meaningful money back in your pocket.

Here's the thing that aerospace companies really care about: field failures are catastrophic for your reputation. The cost of a recall, the liability exposure, the loss of customer trust—these costs dwarf any savings from cheaper, less precise manufacturing. Multi-axis machining produces parts that perform as designed, consistently, every single time.

Because multi-axis machines can optimize tool approach angles, tools last longer and cut more efficiently. Better cutting conditions mean you're getting more parts per tool, which reduces your tool costs and increases production throughput.

Let me break down some specific technical benefits that aerospace engineers and manufacturers care about.

Multi-axis machining typically produces surface finishes that are 20-30% better than conventional machining. For aerospace applications, this matters because:

In many aerospace programs, these enhanced finishes reduce the amount of required post-processing such as polishing or fine deburring.

Many conventional machining operations require secondary processes—hand finishing, deburring, secondary milling operations. Multi-axis machining can often complete the part in its finished state, eliminating these steps entirely.

With multi-axis capability, you can machine features that aren't aligned with a single primary axis simultaneously. Angled holes, boss faces that don't parallel any axis, or complex pockets can all be produced in the time it would take on a conventional machine to set up for a single feature.

Let me give you some concrete examples of aerospace parts that really showcase why multi-axis machining is essential.

Jet engine turbine blades are among the most complex aerospace components. Each blade has an aerodynamic airfoil shape, a root section, cooling holes, and attachment features—all requiring precision work. 5-axis machining is virtually the only practical method for producing these consistently. The same applies to rotor discs with their complex patterns of blade attachment slots and internal passages.

Landing Gear ComponentsLanding gear structural components often need machined pockets, bosses, and mounting surfaces on multiple planes. Multi-axis machining allows these to be produced efficiently without the risk of dimensional errors that could accumulate across multiple setups.

Modern jet engines have casings with internal air passages, external mounting features, and precision bearing surfaces. These casings demand multi-axis machining because the tolerances are tight, the surfaces are complex, and the stakes are high.

Wing components, fuselage brackets, and landing gear support structures often feature lightweighting designs with internal features that are inaccessible to conventional machining. Multi-axis machines unlock the ability to machine these internal features efficiently.

The trend is clear: aerospace manufacturing is moving toward increasingly complex designs requiring increasingly sophisticated machining capabilities. At Ruo Chen, we've invested heavily in multi-axis technology because we know our customers—aerospace companies—demand it.

Emerging technologies like additive manufacturing are getting attention, but for the foreseeable future, multi-axis machining remains the workhorse of aerospace component production. Even as additive methods advance, they'll likely be complemented by multi-axis finishing operations to achieve the surface quality and dimensional accuracy that aerospace demands.

If you're an aerospace company looking to expand your capabilities or a supplier considering this investment, here's what to look for:

Multi-axis machining has become the standard in aerospace because it delivers what the industry demands: precision, consistency, quality, and efficiency. The investment in this technology is substantial, but for both aerospace manufacturers and their suppliers, it's an investment that pays for itself through improved quality, reduced rework, faster production, and most importantly, safer aircraft.

At Ruo Chen, we've seen firsthand how multi-axis capabilities transform our customers' operations. It's not just about having the equipment—it's about having the expertise to use it effectively, the quality systems to guarantee consistency, and the partnership mindset to understand our customers' unique challenges.

If you're in aerospace manufacturing and you're not yet leveraging multi-axis machining, now is the time to explore it. Your competitors are, and your customers certainly expect it. The future of aerospace manufacturing is multi-axis, and the question isn't if you'll adopt it, but when.