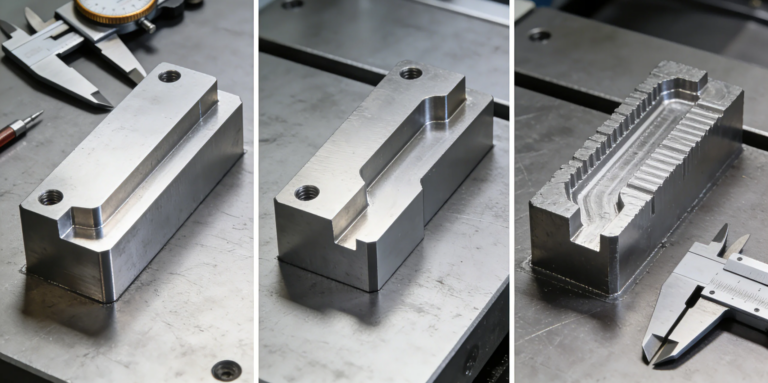

Metals

- Aluminum

- Copper

- Steel

- Stainless Steel

-

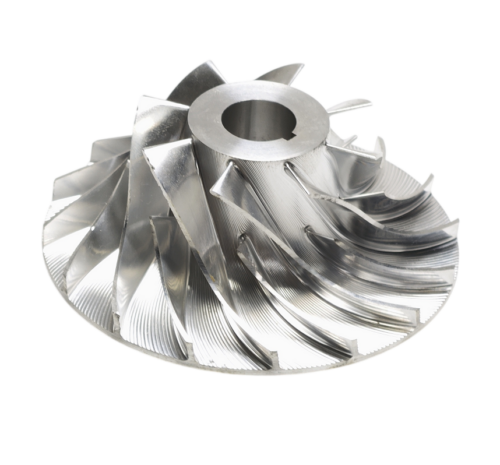

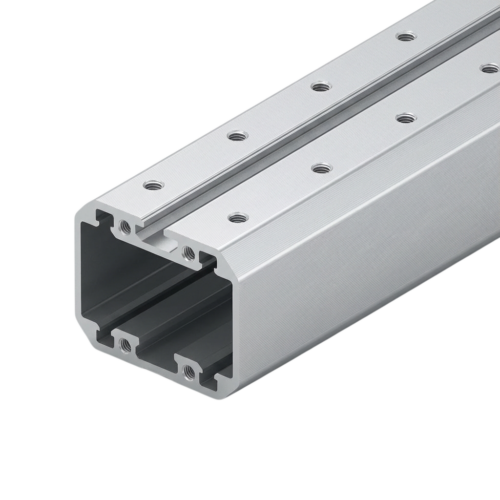

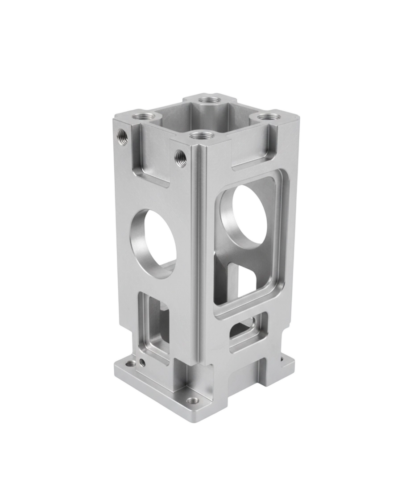

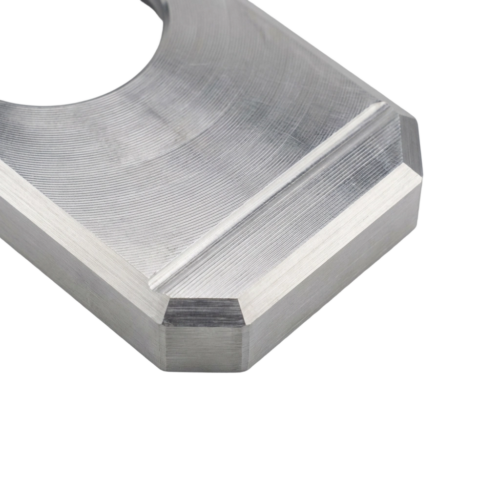

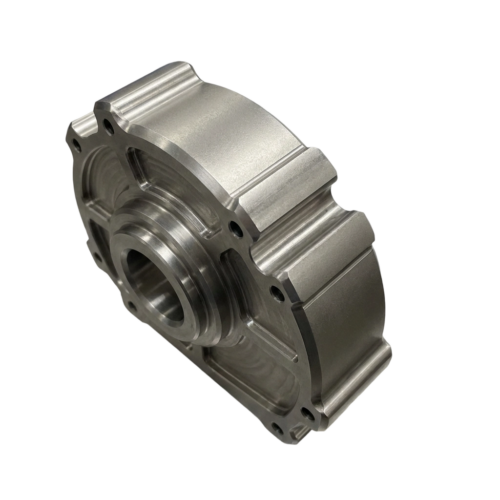

AluminumAluminum is a lightweight, versatile metal widely used in CNC machining for structural and enclosure parts. It offers excellent machinability, good corrosion resistance, and a high strength-to-weight ratio suited for production and prototyping.TypeAluminum 6061 6061-T6 Aluminum 2024 Aluminum 5052 Aluminum 5083

-

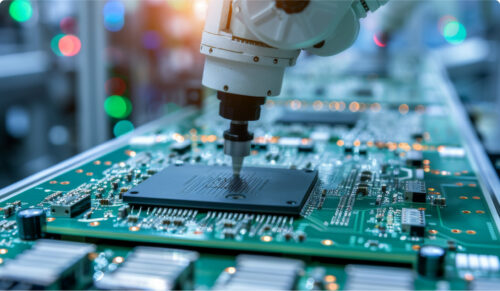

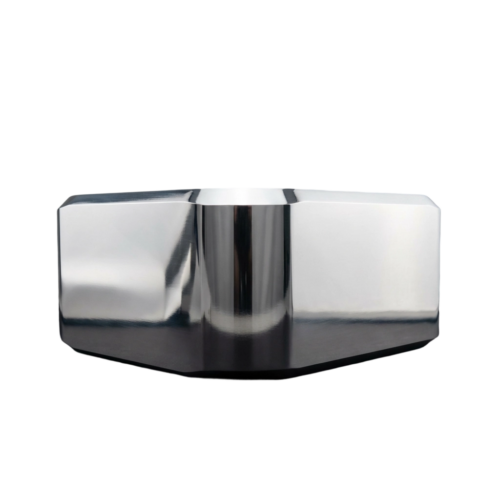

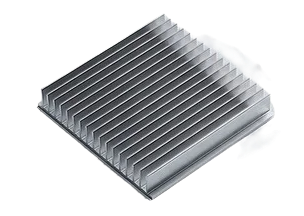

CopperCopper is a versatile, high-conductivity metal widely used in CNC machining for electrical and thermal components. Its excellent ductility and corrosion resistance make it suitable for precision parts, fittings, and heat-transfer assemblies.TypeCopper C110 (ETP) Copper C101 (OFE) Copper C102 (OFHC) Copper C145 (Tellurium Copper)