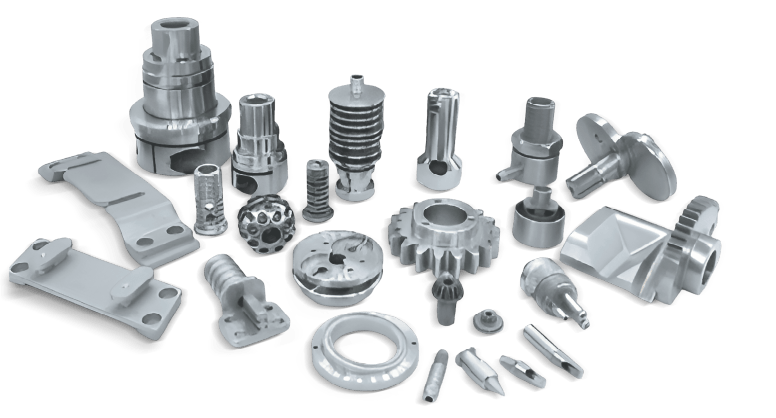

Metals

- Aluminum

- Copper

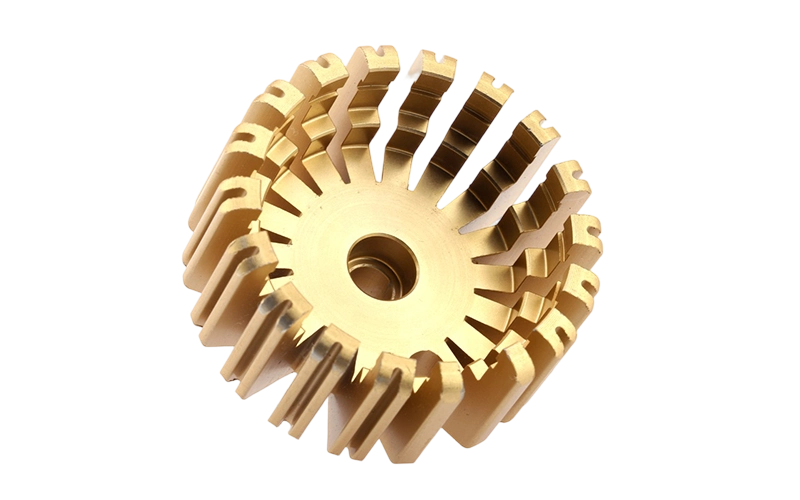

- Brass

- Steel

- Stainless Steel

- Magnesium

- Titanium

-

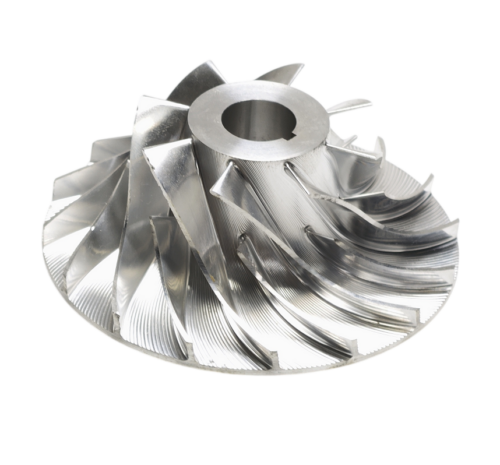

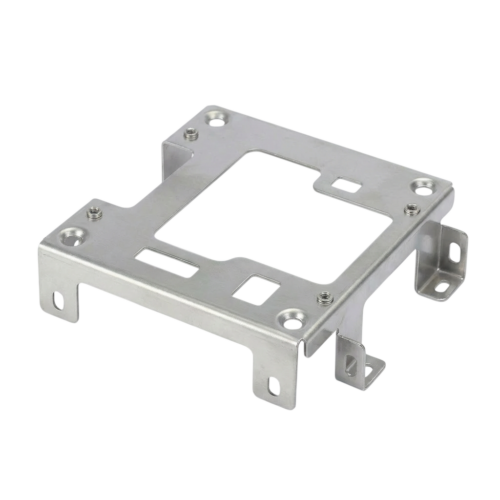

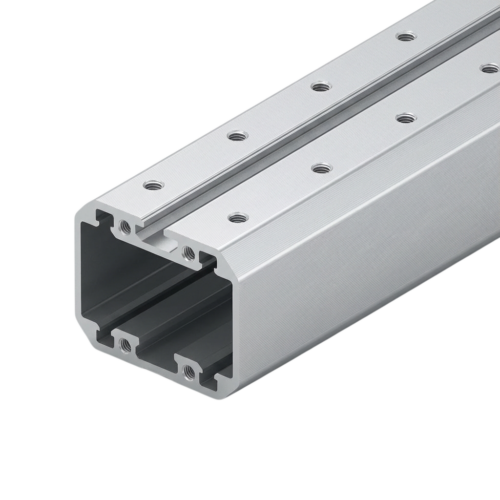

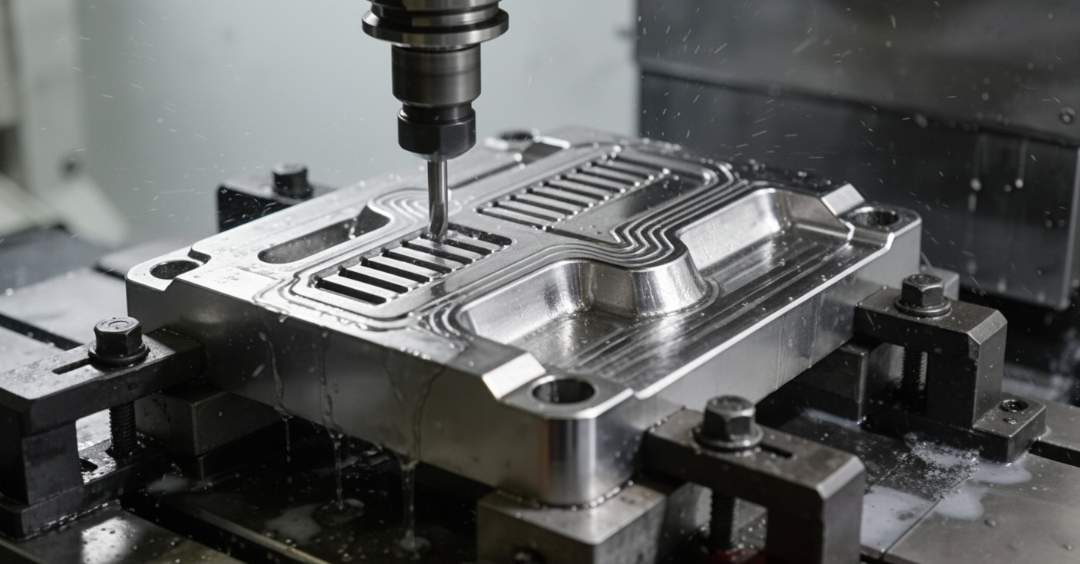

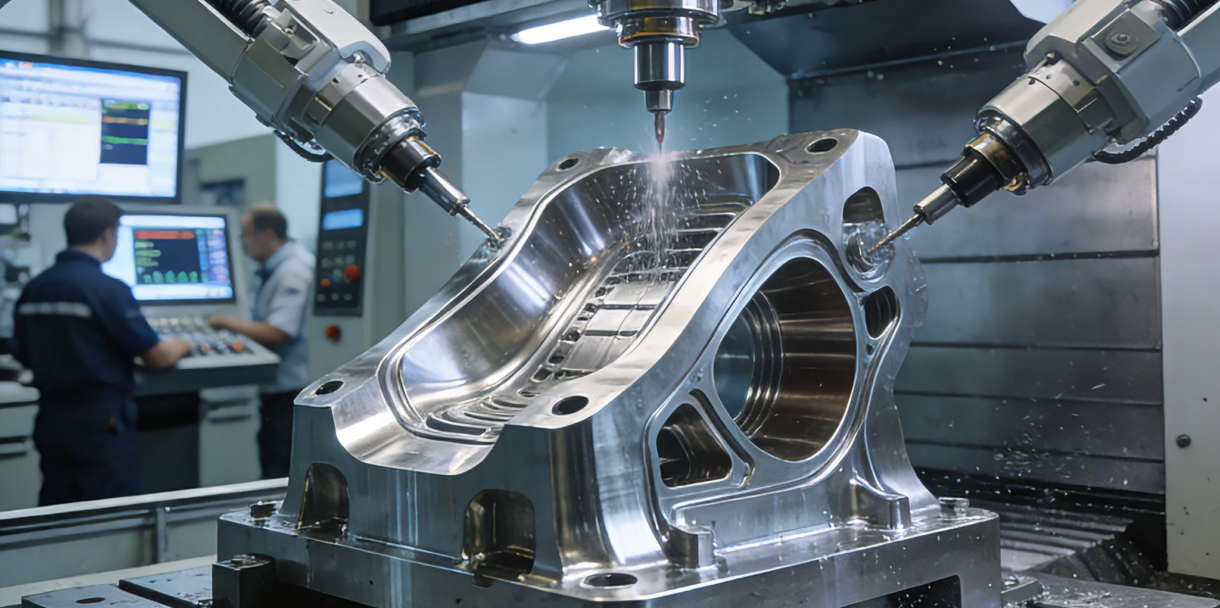

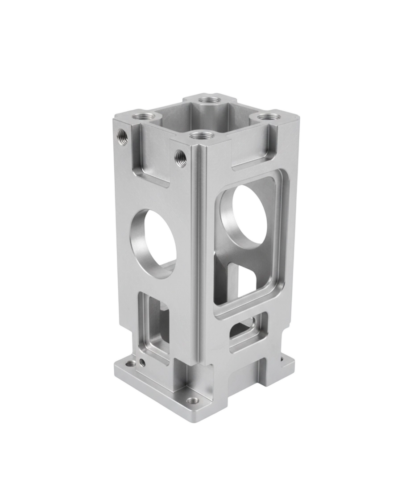

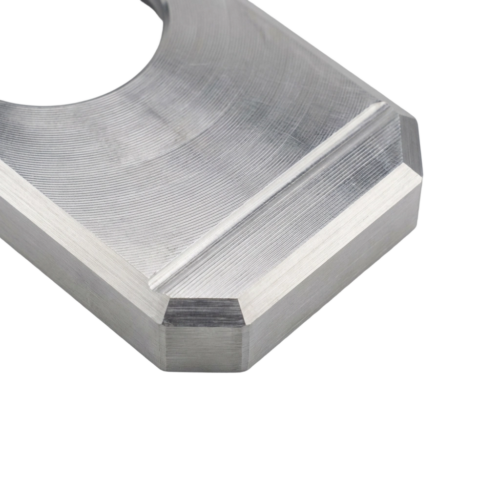

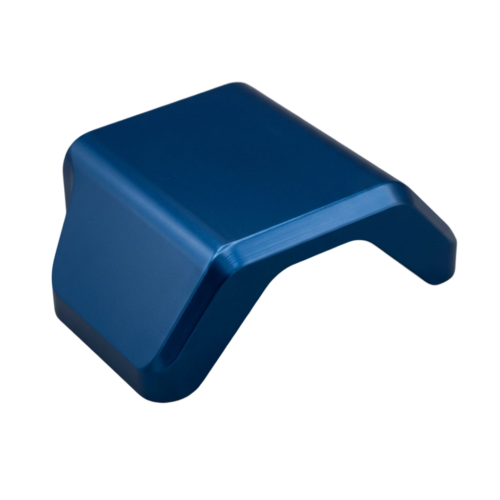

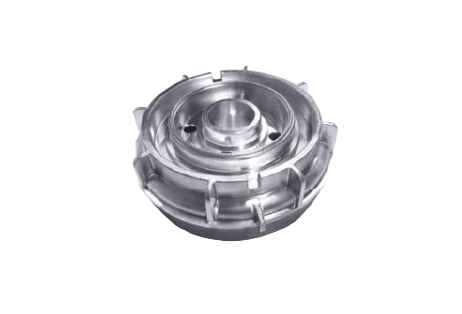

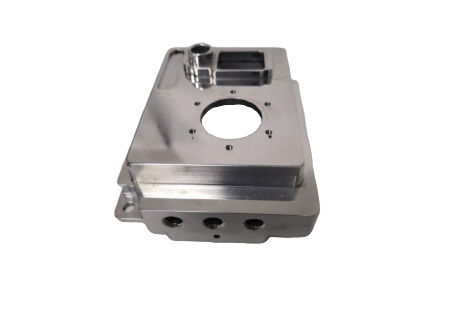

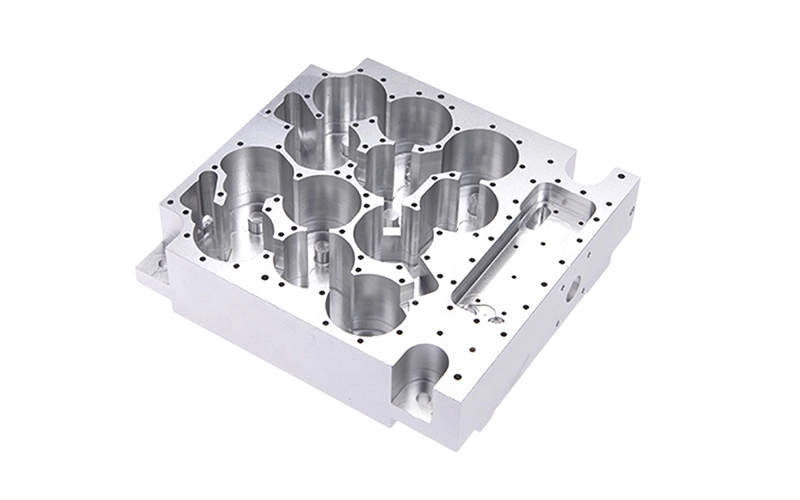

AluminumAluminum is a lightweight, versatile metal widely used in CNC machining for structural and enclosure parts. It offers excellent machinability, good corrosion resistance, and a high strength-to-weight ratio suited for production and prototyping.TypeAluminum 6061 6061-T6 Aluminum 2024 Aluminum 5052 Aluminum 5083

-

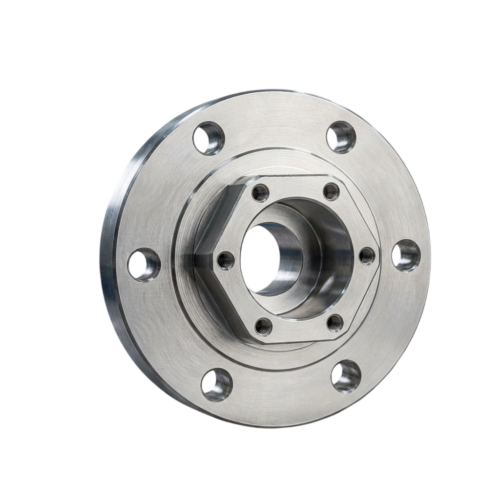

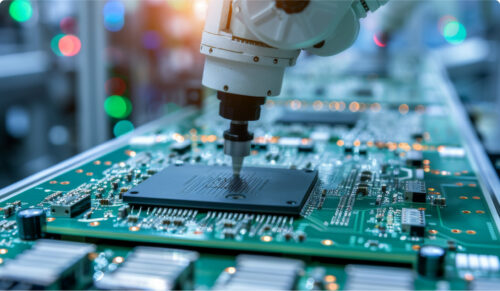

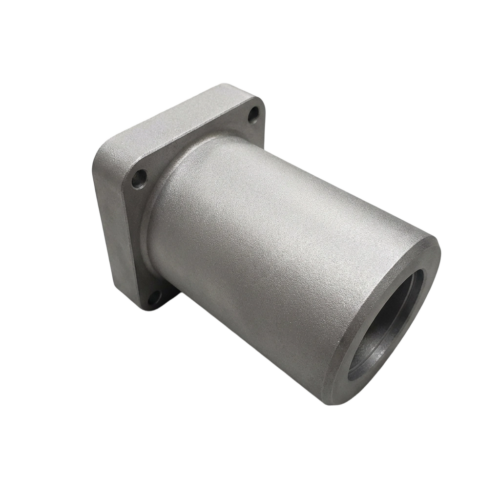

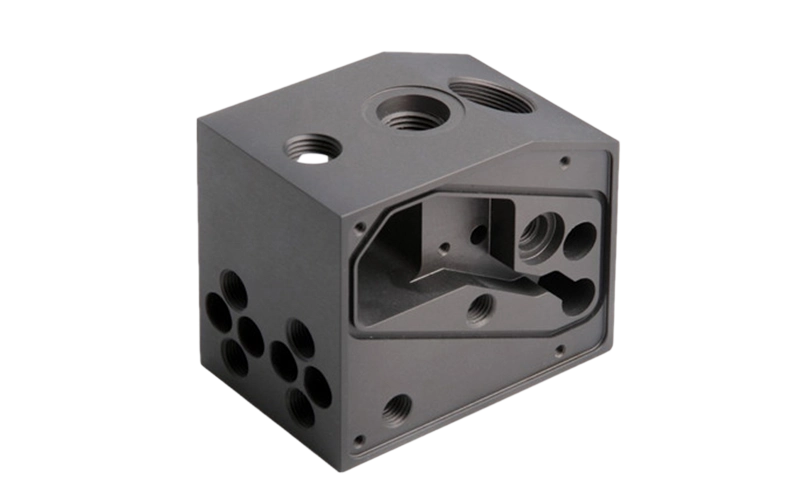

CopperCopper is a versatile, high-conductivity metal widely used in CNC machining for electrical and thermal components. Its excellent ductility and corrosion resistance make it suitable for precision parts, fittings, and heat-transfer assemblies.TypeCopper C110 (ETP) Copper C101 (OFE) Copper C102 (OFHC) Copper C145 (Tellurium Copper)

-

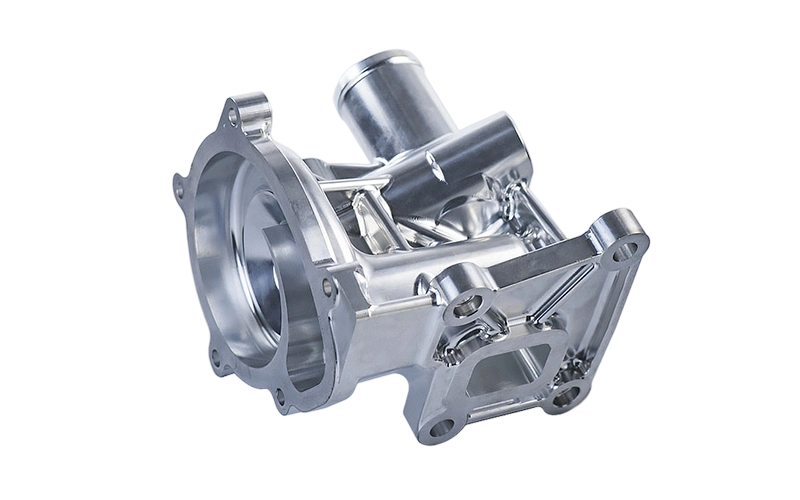

MagnesiumMagnesium is the lightest structural metal, offering an excellent strength-to-weight ratio and fast machinability for CNC and casting processes. Common magnesium alloys provide good thermal conductivity and vibration damping but require corrosion protection and careful chip handling.TypeAZ31B AZ91D AM60B WE43

-

TitaniumTitanium is a lightweight metal offering a superior strength-to-weight ratio and excellent corrosion resistance for demanding CNC-machined parts. It suits aerospace, medical, and industrial applications but requires optimized tooling and coolant control during machining.TypeGrade 5 Grade 23 Grade 2 Grade 1

Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PEEK

- PP

- PTFE (Teflon)

-

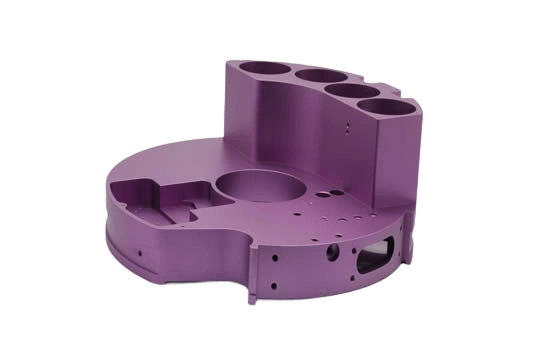

ABSABS (Acrylonitrile Butadiene Styrene) is a versatile engineering thermoplastic offering excellent toughness, impact resistance, and good machinability for prototyping and production parts. It machines cleanly with sharp tooling, accepts paints and adhesives, and is commonly used for housings, trims, and consumer components, with moderate heat and UV limitations.TypeStandard ABS High-impact ABS Flame-retardant ABS

-

PCPolycarbonate (PC) is an impact-resistant engineering thermoplastic with excellent optical clarity, used widely in molded and machined parts. It suits prototypes and production components where toughness, transparency, and dimensional stability are required.TypeStandard PC Optical-Grade PC Flame-Retardant PC

-

POMPOM (polyoxymethylene) is a high-performance engineering thermoplastic known for stiffness, low friction, and excellent dimensional stability for machined parts. It offers superior machinability and wear resistance for precision components used in industrial and consumer applications.TypeStandard POM (Acetal) Glass-Filled POM Low-Friction POM

-

PA (Nylon)PA (Nylon) is a versatile engineering thermoplastic known for toughness, low friction, and excellent wear resistance. It suits CNC machining and injection molding for structural and bearing components but is hygroscopic, so plan for moisture-related dimensional changes.TypePA6 (Nylon 6) PA66 (Nylon 66) Glass-Filled PA

-

PEEKPEEK (polyether ether ketone) is a high-performance semicrystalline thermoplastic with exceptional mechanical, thermal, and chemical properties. It offers dimensional stability and low wear for precision CNC machining and demanding manufacturing applications.TypeUnfilled PEEK Glass-Filled PEEK Carbon-Filled PEEK

-

PPPP (polypropylene) is a semi-crystalline thermoplastic widely used for CNC machining and injection molding. It combines low density, excellent chemical resistance, low moisture uptake, and good fatigue performance for cost-effective, high-volume parts.TypeHomopolymer PP Copolymer PP Glass-Filled PP

-

PTFE (Teflon)PTFE (Teflon) is a high-performance fluoropolymer prized for ultra-low friction, wide temperature stability, and outstanding chemical resistance. It is commonly CNC-machined into seals, bearings, electrical insulators, and corrosion-resistant components; filled grades improve wear and dimensional stability.TypeVirgin PTFE Carbon-Filled PTFE