Chinese (Simplified)

English

German

Korean

Spanish

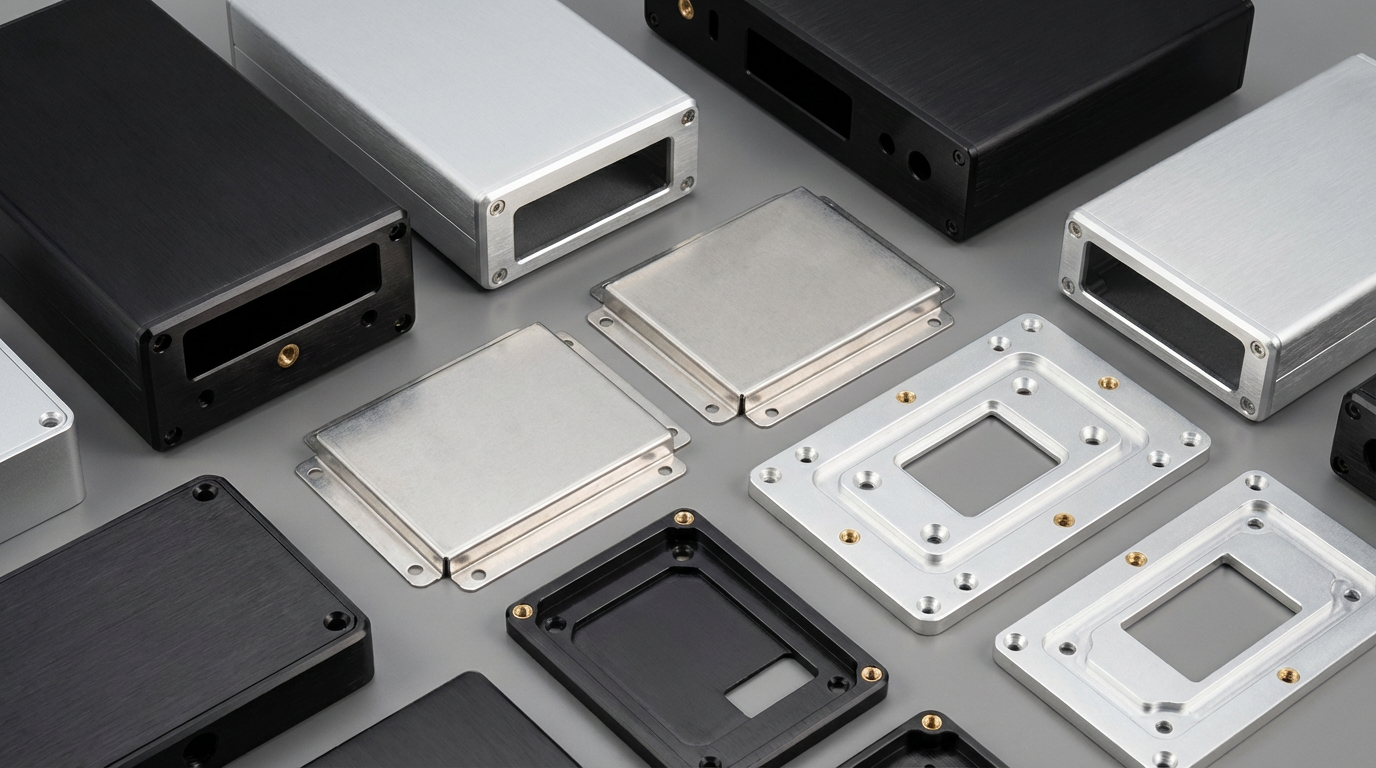

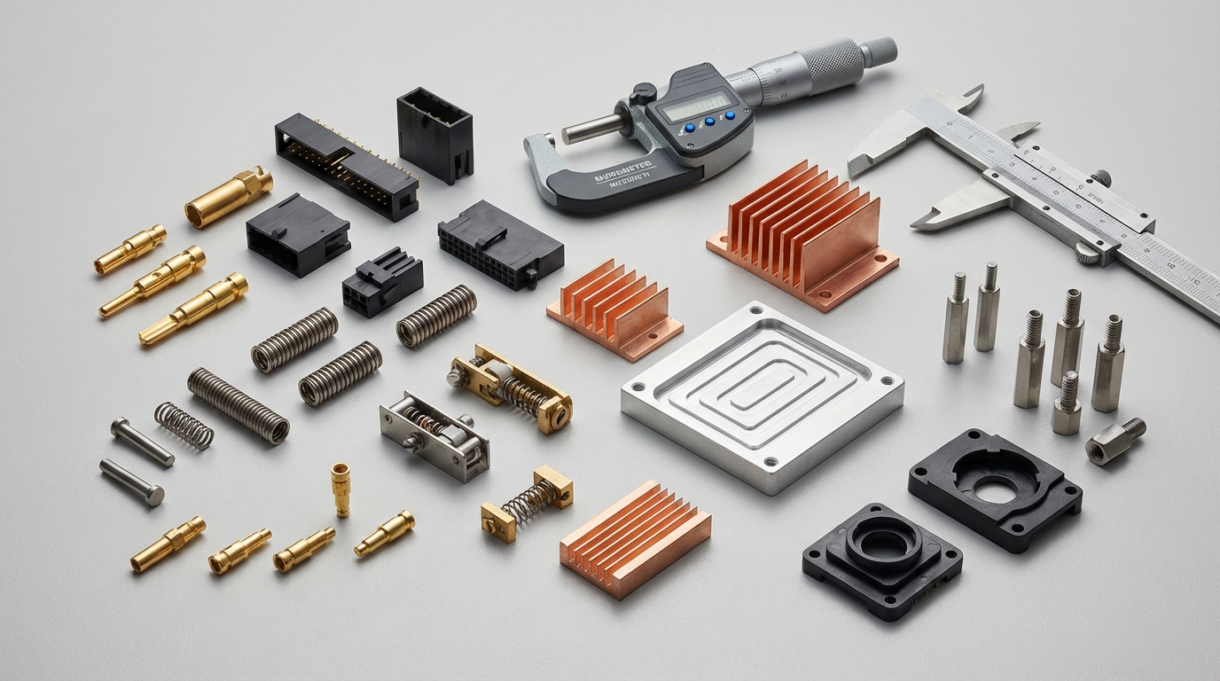

We combine precision machining, strict quality control, and electronics-focused assembly to meet industry requirements.

Typical components we machine for the electronics sector include structural, thermal, and connector parts.

We provide end-to-end CNC machining services to support your project from prototype to mass production.

We machine a wide range of metals and engineering plastics chosen for conductivity, weight, and EMI performance. Standard finishing options support corrosion resistance, conductivity, and assembly cleanliness.