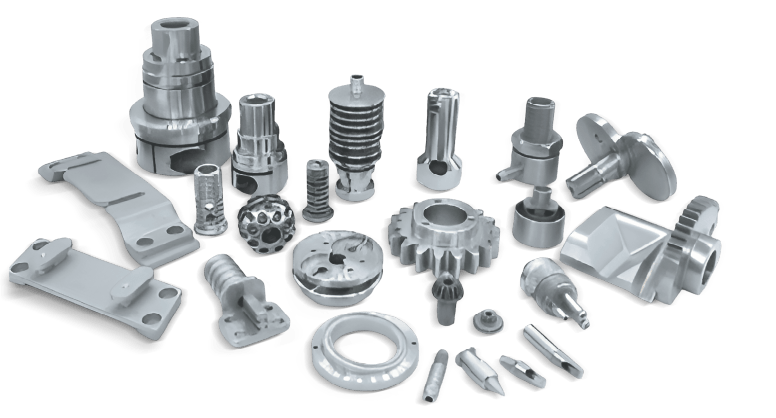

Metals

- Aluminum

- Brass

- Magnesium

-

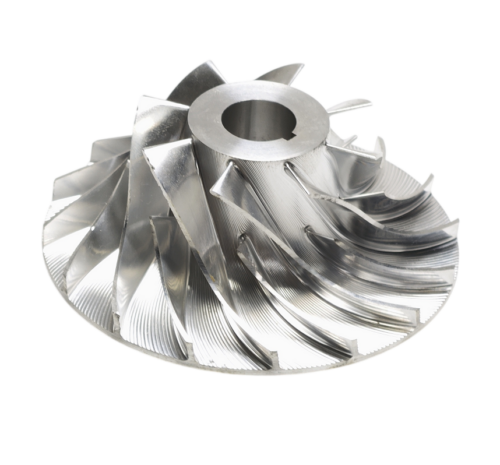

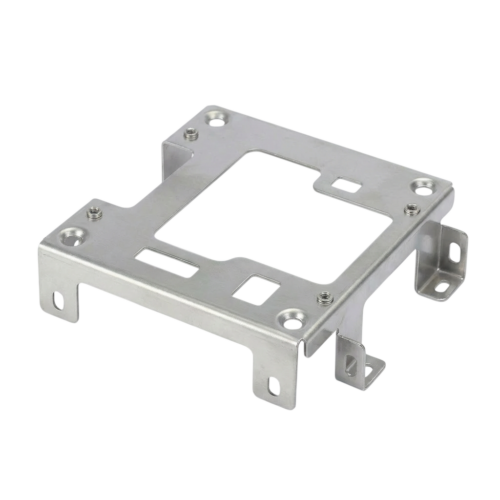

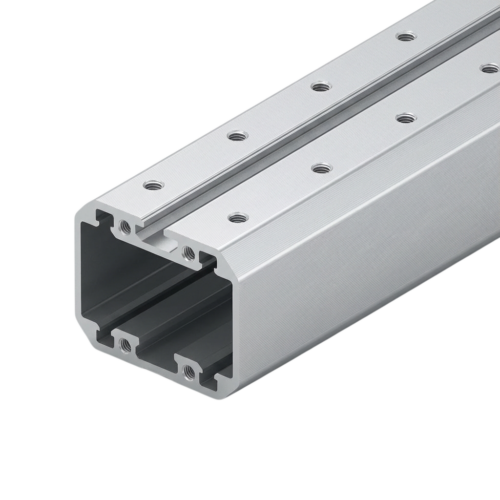

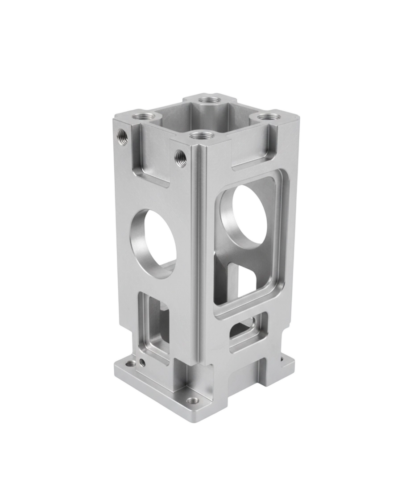

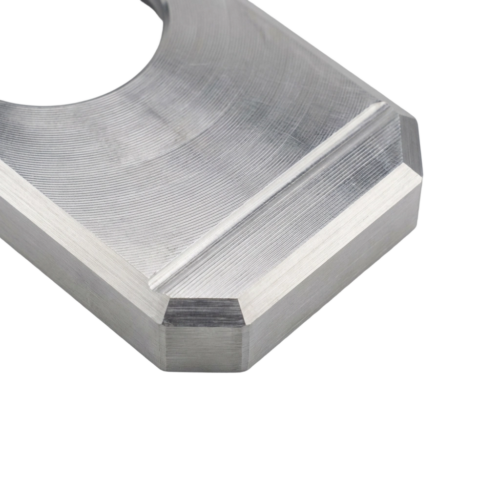

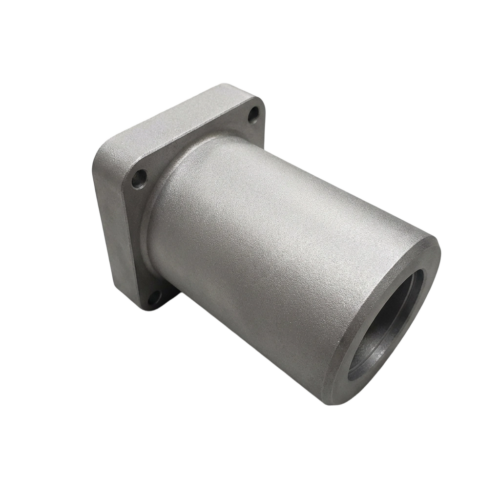

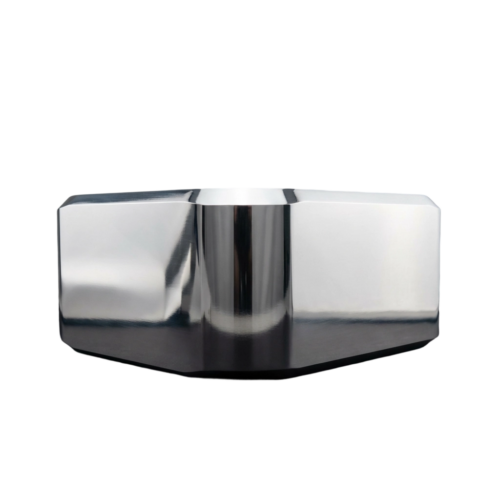

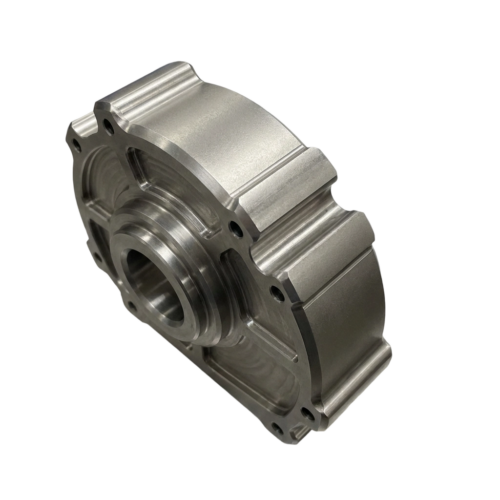

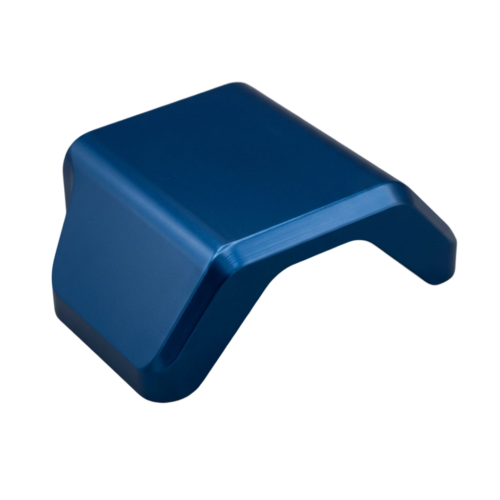

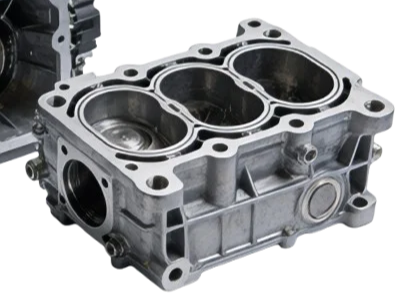

AluminumAluminum is a lightweight, versatile metal widely used in CNC machining for structural and enclosure parts. It offers excellent machinability, good corrosion resistance, and a high strength-to-weight ratio suited for production and prototyping.TypeAluminum 6061 6061-T6 Aluminum 2024 Aluminum 5052 Aluminum 5083

-

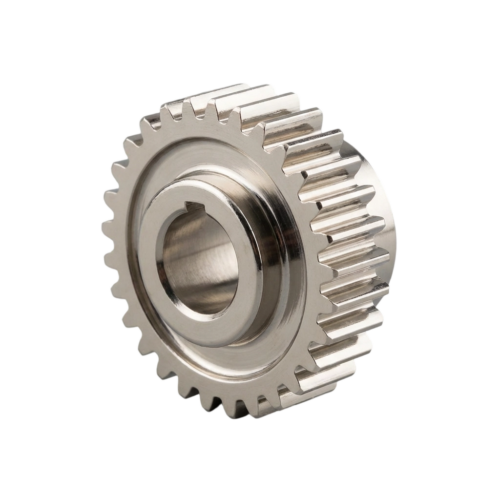

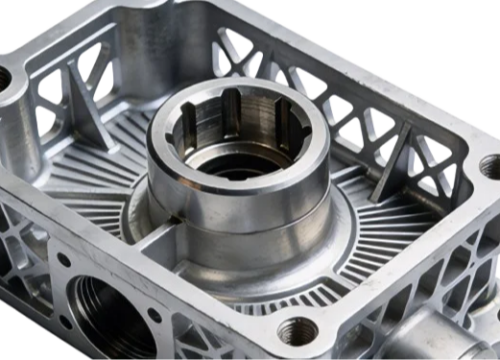

MagnesiumMagnesium is the lightest structural metal, offering an excellent strength-to-weight ratio and fast machinability for CNC and casting processes. Common magnesium alloys provide good thermal conductivity and vibration damping but require corrosion protection and careful chip handling.TypeAZ31B AZ91D AM60B WE43