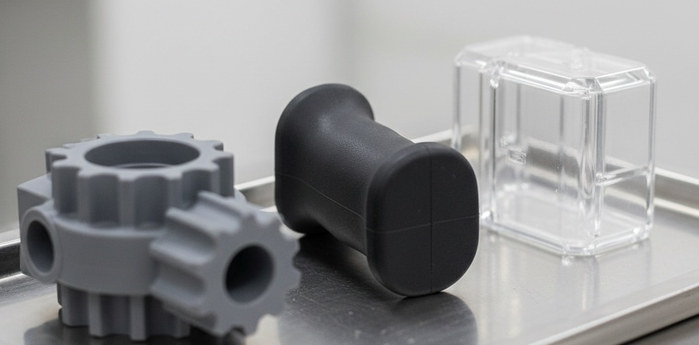

Plastics

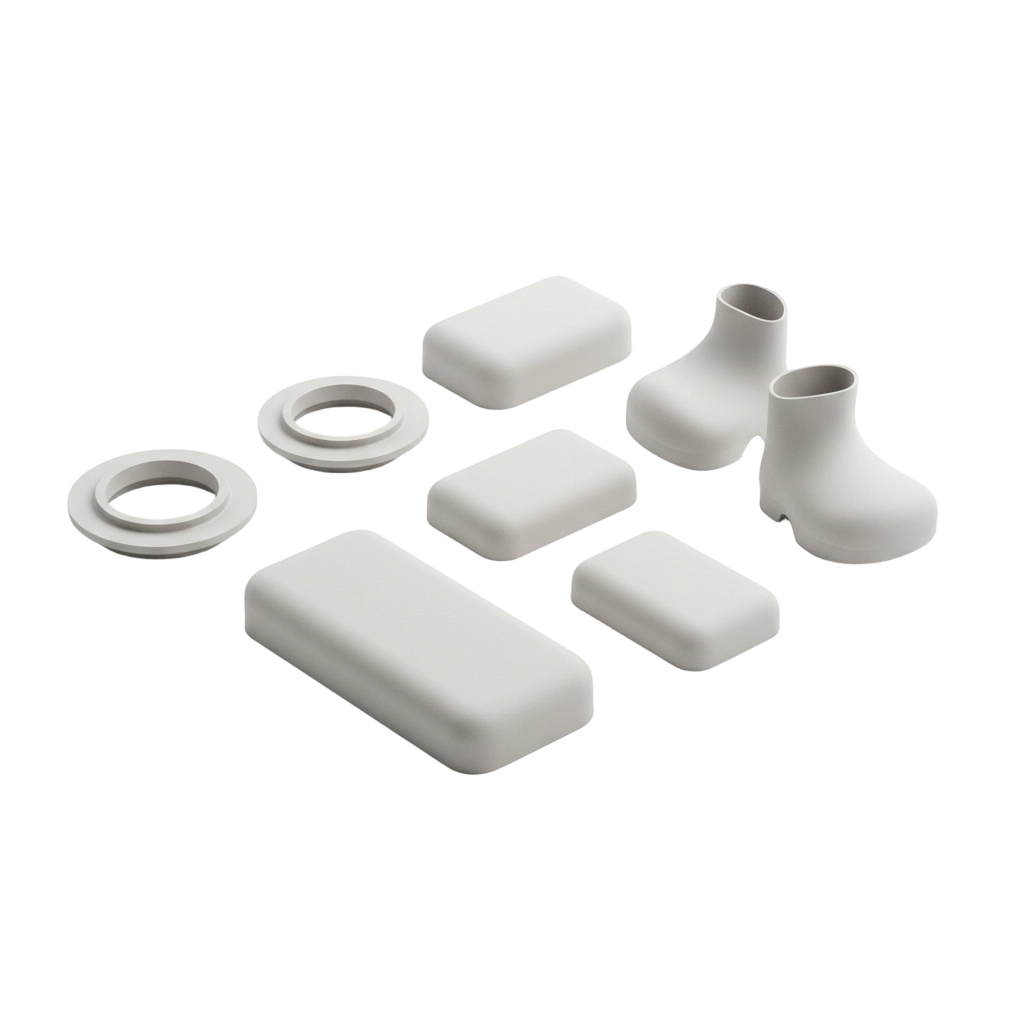

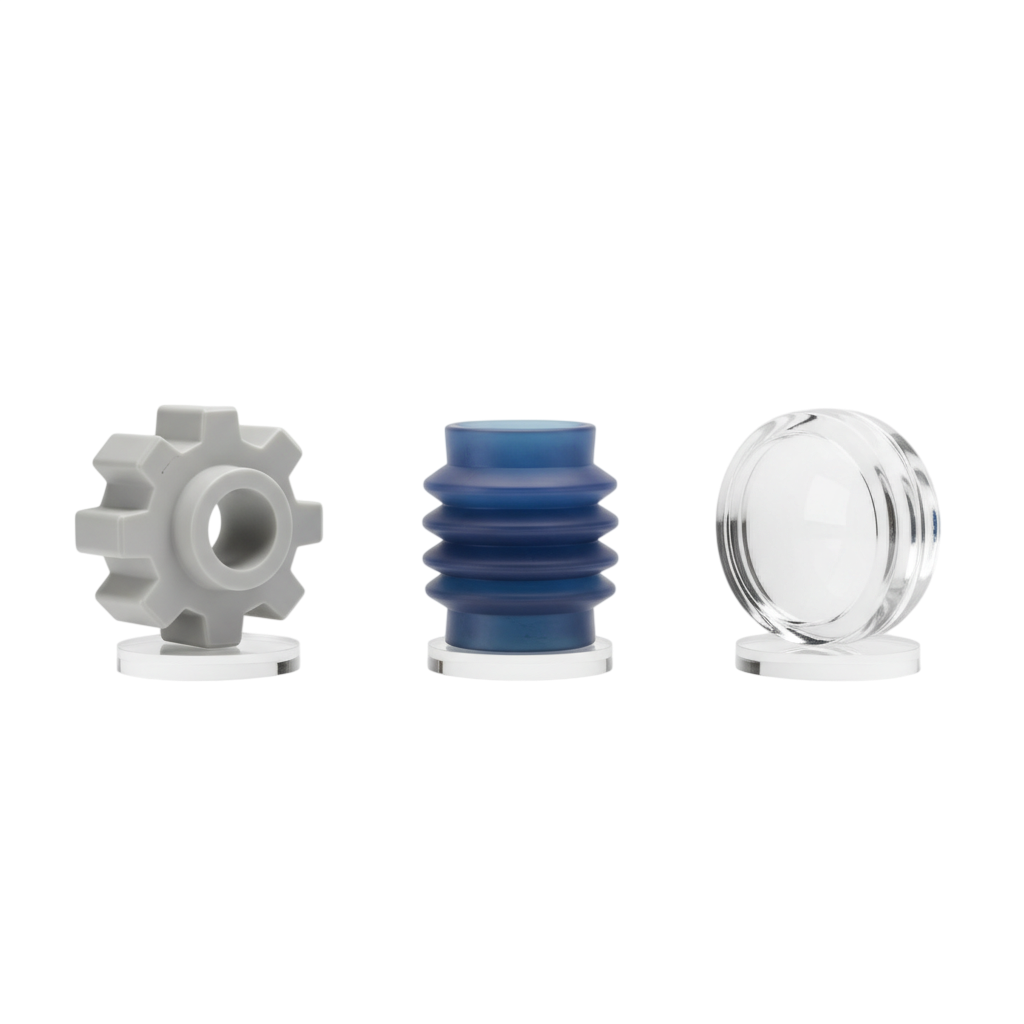

- PU Resin

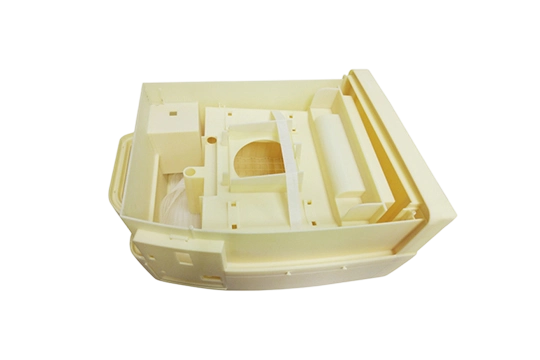

- Epoxy Resin

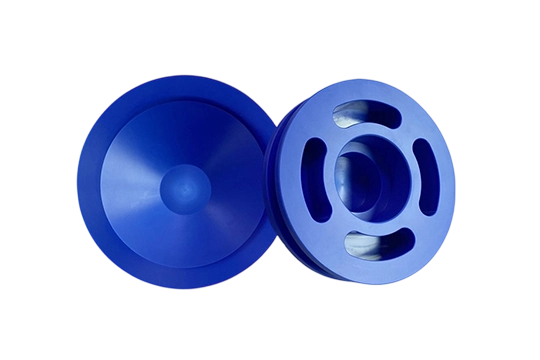

- Silicone

-

PU ResinPU Resin (polyurethane resin) is the most widely used material for vacuum casting, offering flexible formulation options from soft, rubber-like parts to rigid grades that simulate ABS or PC. It supports cosmetic prototypes and low-volume production with good surface finish, plus options for clear, high-temperature, and flame-retardant requirements.TypeSoft PU Rigid PU Clear PU High-temp PU

-

Epoxy ResinEpoxy Resin (EP) is a rigid thermoset resin used for casting and prototyping parts that require high strength, dimensional stability, and reliable electrical insulation. It can be supplied in high-strength, clear, and high-temperature formulations, with post-curing options to improve performance for functional prototypes and low-volume production components.TypeHigh-Strength Epoxy Clear Epoxy High-Temp Epoxy

-

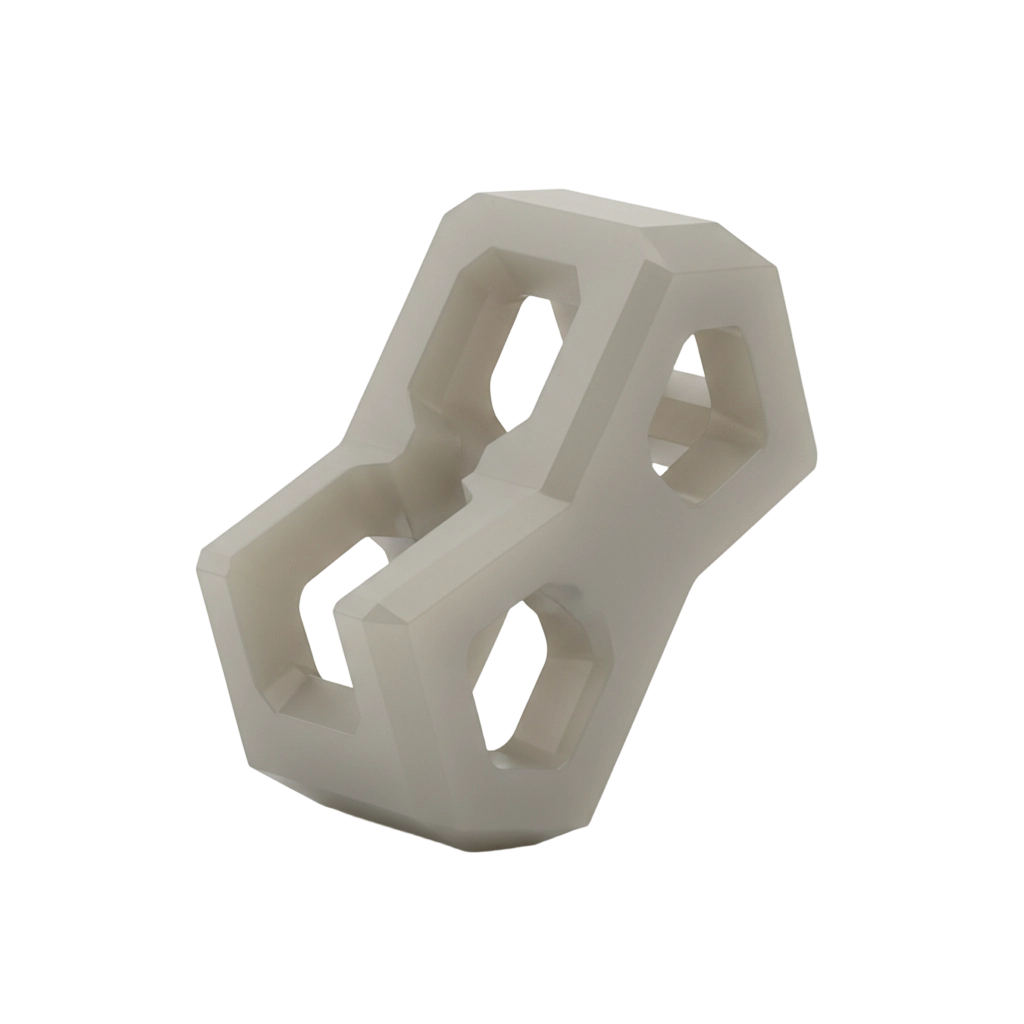

SiliconeSilicone (addition-cure, platinum-cure) is primarily used to make flexible, high-accuracy molds for vacuum casting and prototype replication. It features low shrinkage, good tear strength, and easy release, enabling reliable reproduction of complex geometries and fine surface details across multiple casting cycles.TypePlatinum-Cure Silicone Transparent Silicone High-Temperature Silicone Shore A 10–40 Silicone