Chinese (Simplified)

English

German

Korean

Spanish

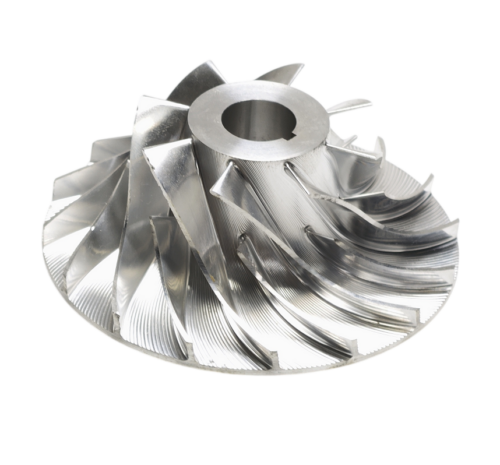

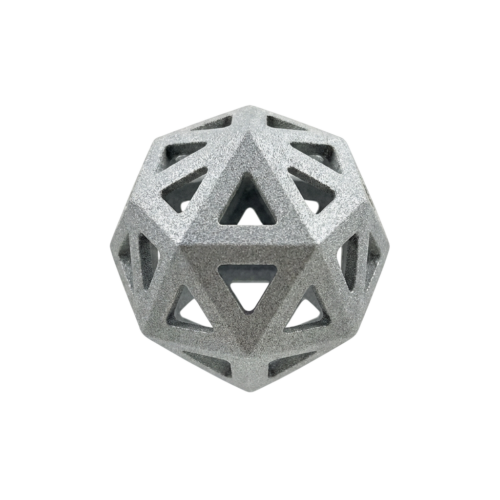

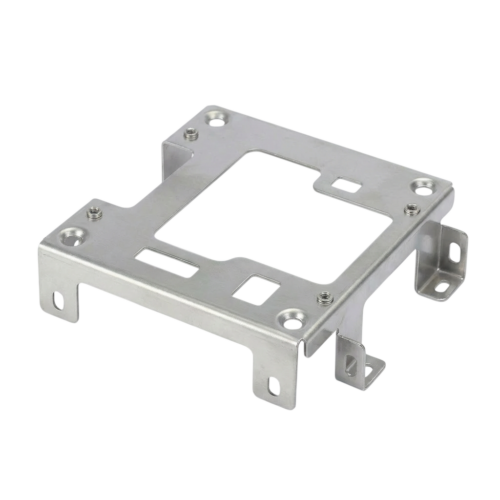

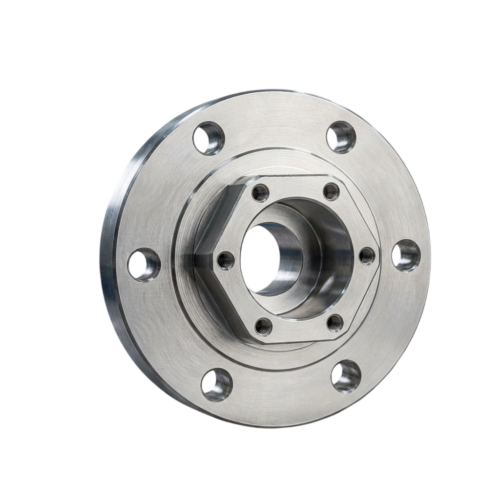

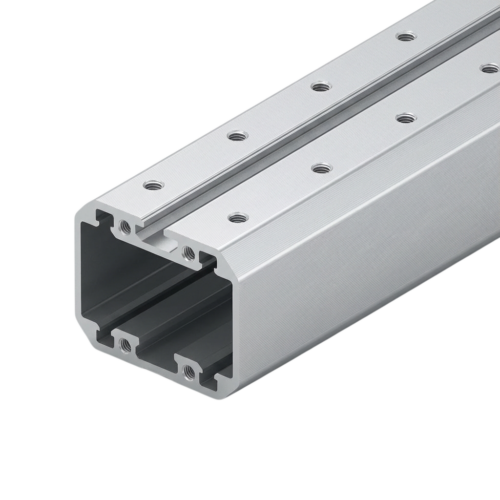

RuoChen Precision offers complete CNC manufacturing services to support your project at any stage—prototype, small batch, or full-scale mass production.

Founded in 2008, RuoChen Precision Manufacturing is based in Dongguan, China, operating a modern 10,000 m² facility with advanced CNC equipment and an experienced engineering and quality team.

We support global customers across electronics, medical, automotive, aerospace, and industrial equipment—delivering stable quality, responsive communication, and manufacturing solutions that scale with your product roadmap.

We create fast, accurate CNC prototypes with professional CAD/CAM programming to validate function, fit, and assembly before committing to volume production.

Our engineers review manufacturability, optimize toolpaths, and recommend cost-saving adjustments—so your samples match real production requirements.

A clear 5-step workflow from requirements to delivery—fast, transparent, and quality-focused.