Chinese (Simplified)

English

German

Korean

Spanish

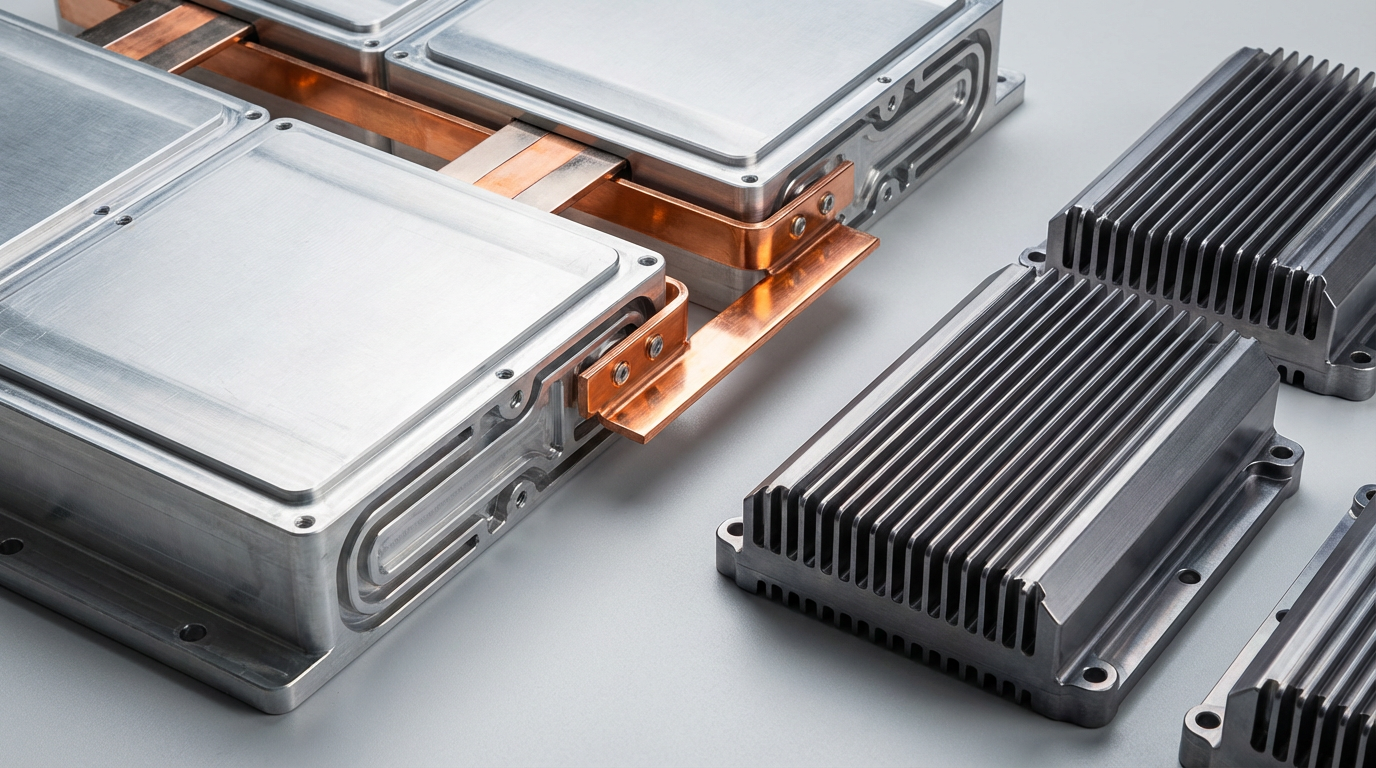

Manufacturers trust us to produce durable, high-performance parts for next-generation energy systems.

Typical components we machine across renewables, energy storage, and hydrogen technologies.

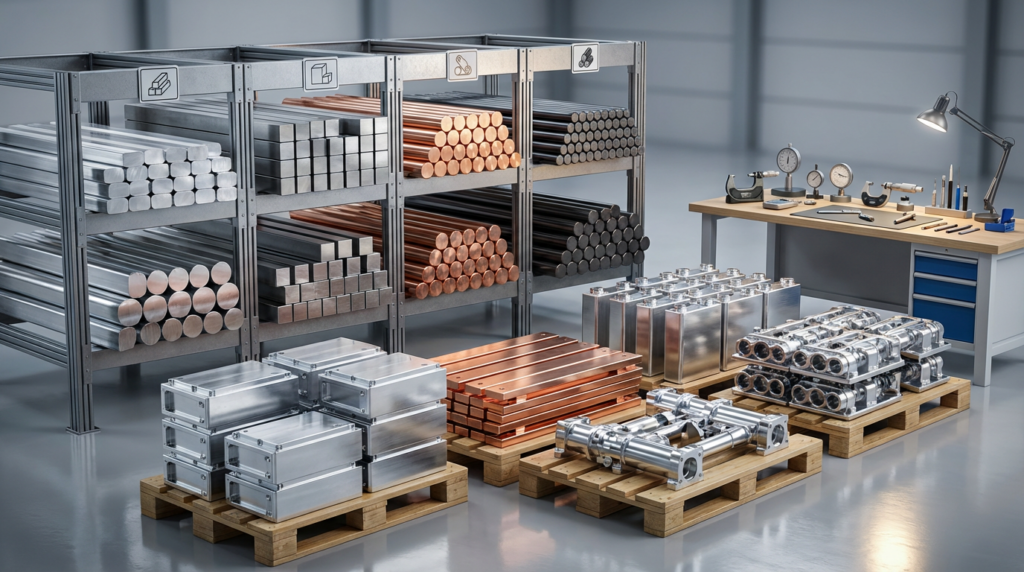

We provide end-to-end CNC machining services to support your project from prototype to mass production.

We machine a broad range of metals and alloys suited to electrical conductivity, corrosion resistance, and high-temperature service. Standard finishing options meet industry requirements for protection and assembly.