Plastics

- ABS

- PC

- PMMA (Acrylic)

- POM

- PA (Nylon)

- PE

- PEEK

- PP

- PBT

- PVC

- PS

- PET

-

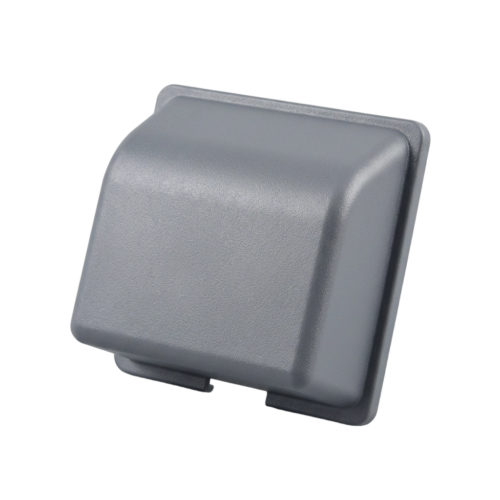

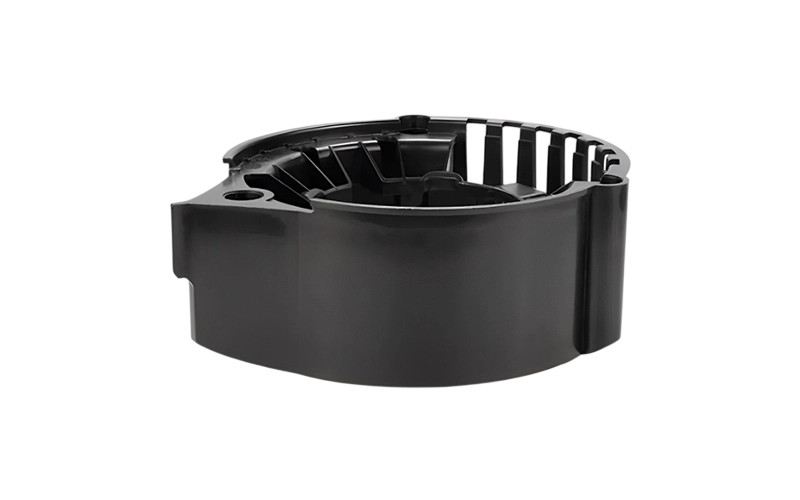

ABSABS (Acrylonitrile Butadiene Styrene) is a versatile engineering thermoplastic offering excellent toughness, impact resistance, and good machinability for prototyping and production parts. It machines cleanly with sharp tooling, accepts paints and adhesives, and is commonly used for housings, trims, and consumer components, with moderate heat and UV limitations.TypeStandard ABS High-impact ABS Flame-retardant ABS

-

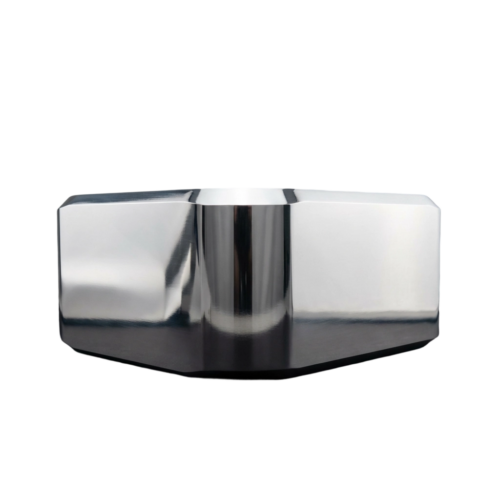

PCPolycarbonate (PC) is an impact-resistant engineering thermoplastic with excellent optical clarity, used widely in molded and machined parts. It suits prototypes and production components where toughness, transparency, and dimensional stability are required.TypeStandard PC Optical-Grade PC Flame-Retardant PC

-

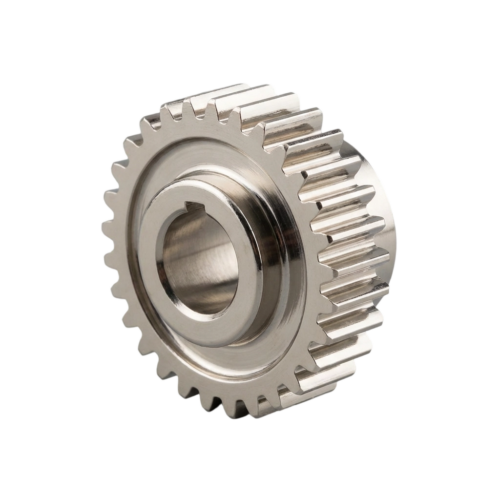

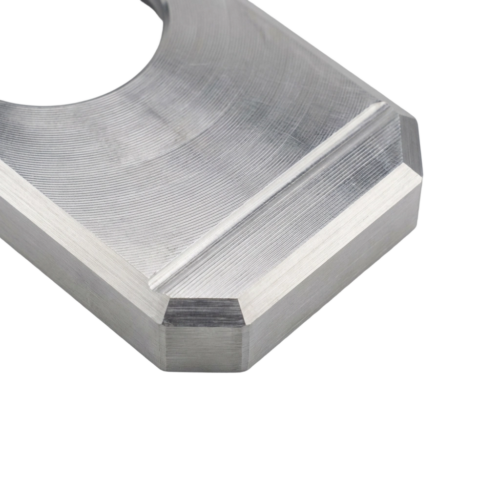

POMPOM (polyoxymethylene) is a high-performance engineering thermoplastic known for stiffness, low friction, and excellent dimensional stability for machined parts. It offers superior machinability and wear resistance for precision components used in industrial and consumer applications.TypeStandard POM (Acetal) Glass-Filled POM Low-Friction POM

-

PA (Nylon)PA (Nylon) is a versatile engineering thermoplastic known for toughness, low friction, and excellent wear resistance. It suits CNC machining and injection molding for structural and bearing components but is hygroscopic, so plan for moisture-related dimensional changes.TypePA6 (Nylon 6) PA66 (Nylon 66) Glass-Filled PA

-

PEEKPEEK (polyether ether ketone) is a high-performance semicrystalline thermoplastic with exceptional mechanical, thermal, and chemical properties. It offers dimensional stability and low wear for precision CNC machining and demanding manufacturing applications.TypeUnfilled PEEK Glass-Filled PEEK Carbon-Filled PEEK

-

PPPP (polypropylene) is a semi-crystalline thermoplastic widely used for CNC machining and injection molding. It combines low density, excellent chemical resistance, low moisture uptake, and good fatigue performance for cost-effective, high-volume parts.TypeHomopolymer PP Copolymer PP Glass-Filled PP

-

PBTPBT (polybutylene terephthalate) is a semi-crystalline engineering thermoplastic offering excellent dimensional stability, mechanical strength, and electrical insulation. It molds and machines well, with glass-filled and flame-retardant grades available for heat-resistant automotive, electrical, and consumer components.TypeStandard PBT Glass-Filled PBT Flame-Retardant PBT

-

PVCPolyvinyl chloride (PVC) is a versatile thermoplastic available in rigid and flexible grades, offering strong chemical resistance, flame retardancy, and good dimensional stability. It machines well with standard tooling, bonds and welds readily, and provides a cost-effective option for piping, jacketing, and fabricated components.TypeRigid PVC (uPVC) Flexible PVC CPVC

-

PSPolystyrene (PS) is an amorphous, low-cost thermoplastic commonly used for injection molding, thermoforming, and prototyping. It provides excellent surface finish and dimensional stability, with limited heat and chemical resistance.TypeGeneral Purpose PS (GPPS) High Impact PS (HIPS) Expandable PS (EPS)

-

PETPolyethylene terephthalate (PET) is a semi-crystalline engineering thermoplastic offering high stiffness, dimensional stability, and strong chemical resistance. It is widely used in injection molding, extrusion, and CNC machining for structural, electrical, and food-contact components.TypeUnfilled PET Glass-Filled PET Recycled PET (rPET)