Chinese (Simplified)

English

German

Korean

Spanish

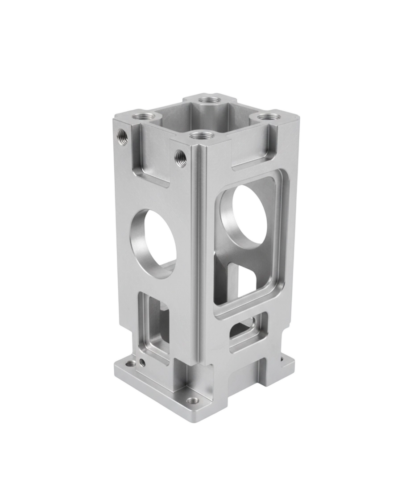

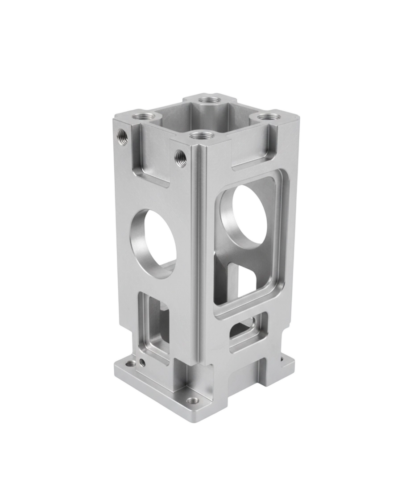

We support CNC machining across a wide range of metals and plastics, suitable for both prototyping and production.

Aluminum

Copper

Bronze

Brass

Steel

Stainless Steel

Magnesium

Titanium

Alloy 6061

Alloy 6063

ABS

PC

PMMA (Acrylic)

POM

PA (Nylon)

PE

PEEK

PP

HDPE

FR-4

RuoChen Precision works with carefully selected materials to ensure strength, stability, and reliable machining performance across all applications.

Aluminum is a lightweight, versatile metal widely used in CNC machining for structural and enclosure parts. It offers excellent machinability, good corrosion resistance, and a high strength-to-weight ratio suited for production and prototyping.

Used for engine brackets, housings, and body panels requiring lightweight strength.

Machined airframe parts and fittings where high strength-to-weight is critical.

Enclosures and heat spreaders offering EMI shielding and thermal management.

ABS (Acrylonitrile Butadiene Styrene) is a versatile engineering thermoplastic offering excellent toughness, impact resistance, and good machinability for prototyping and production parts. It machines cleanly with sharp tooling, accepts paints and adhesives, and is commonly used for housings, trims, and consumer components, with moderate heat and UV limitations.

Common for instrument housings and protective covers due to stiffness and finishability.

Used for trim, panels and vents where impact resistance and cost efficiency are required.

Ideal for functional prototypes and fit checks; easy to machine and modify.

Choosing the right material is essential for achieving the required strength and performance in CNC machining. Below are common questions our customers ask when selecting metals or plastics for their projects.