Chinese (Simplified)

English

German

Korean

Spanish

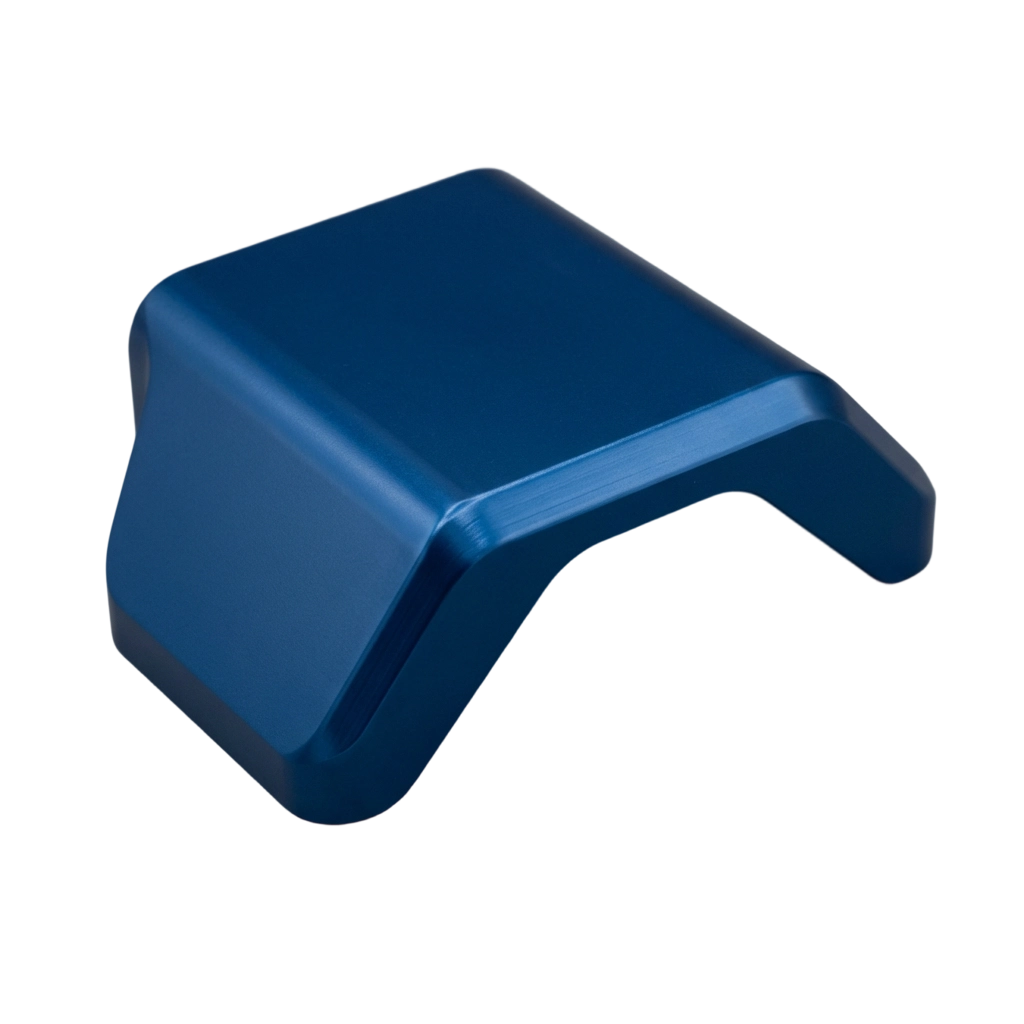

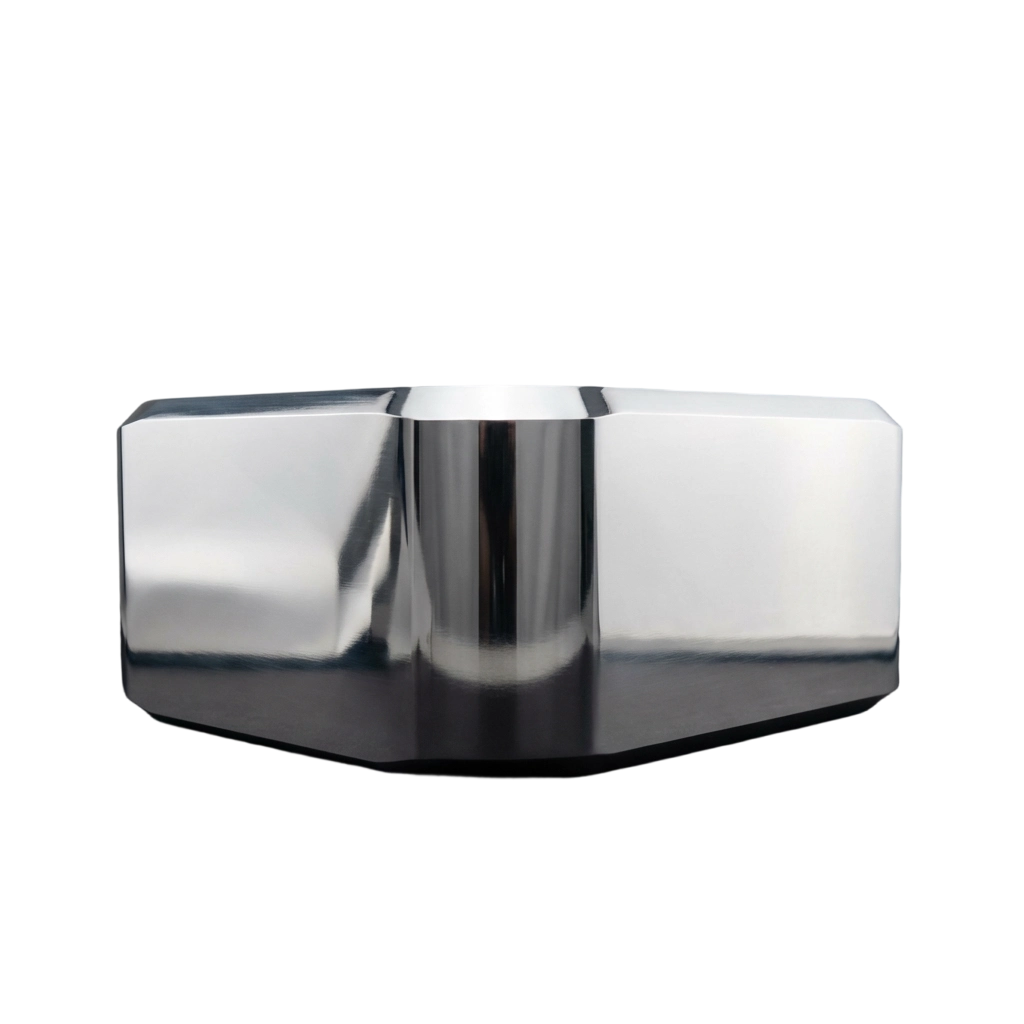

Surface finishes are applied after machining to refine part surfaces beyond their raw machined state. These processes help reduce visible machining marks, enhance surface integrity, and support requirements such as corrosion protection, friction reduction, or coating readiness. Different finishes are selected based on material type, part geometry, and end-use expectations across CNC machining and related manufacturing processes.

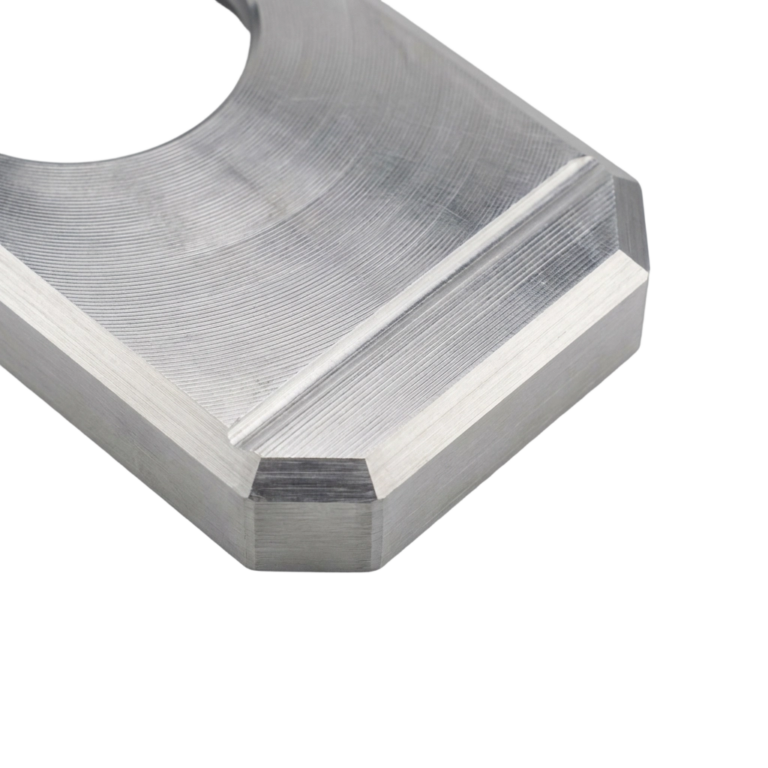

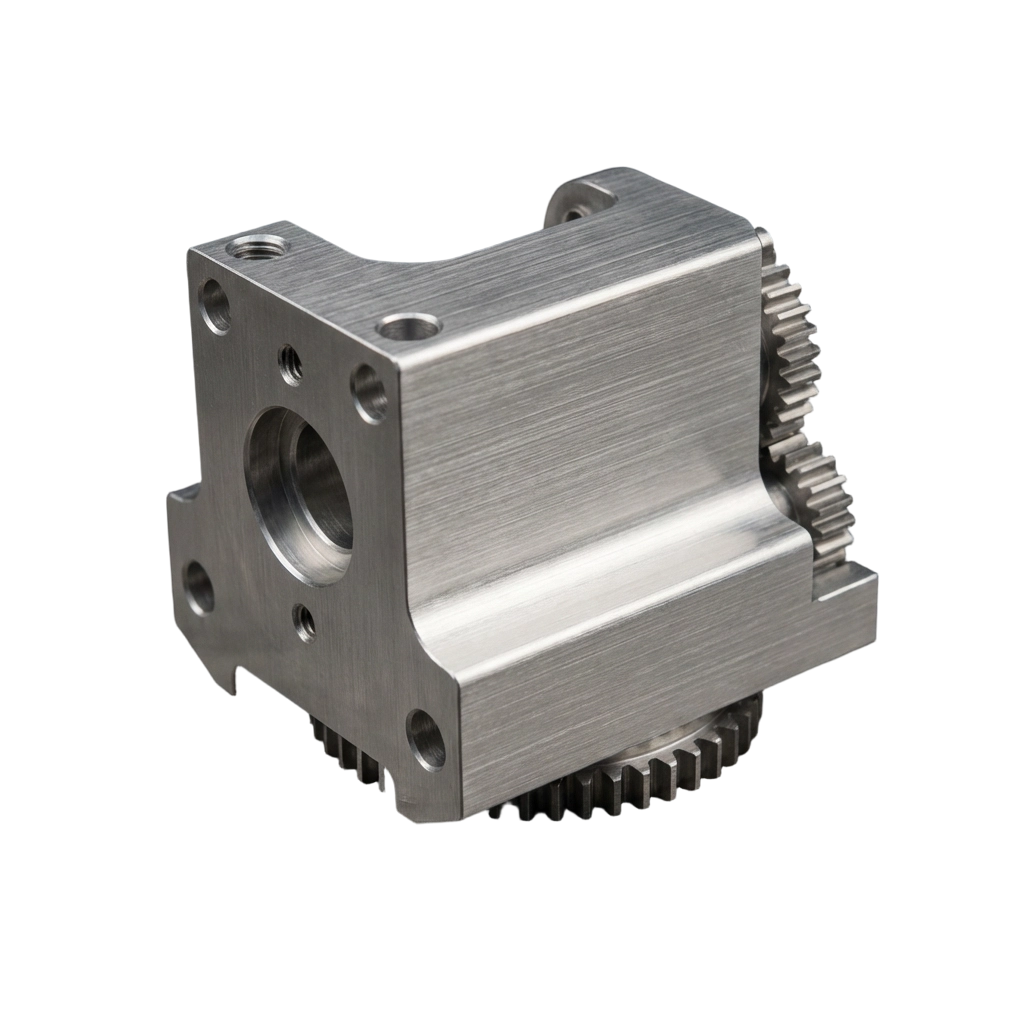

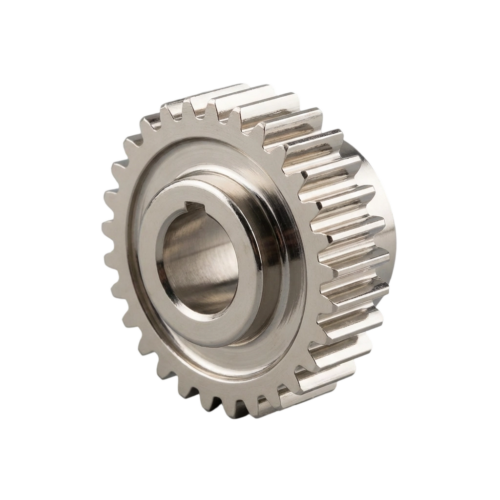

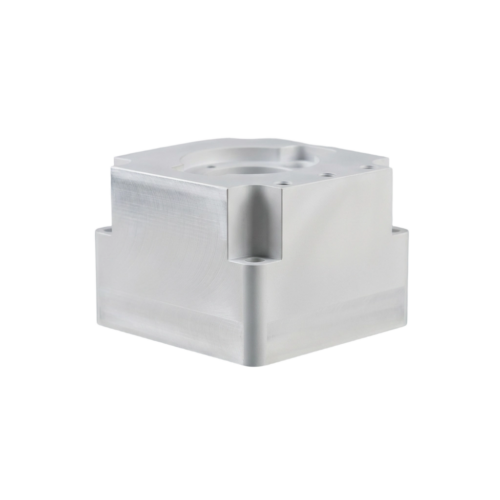

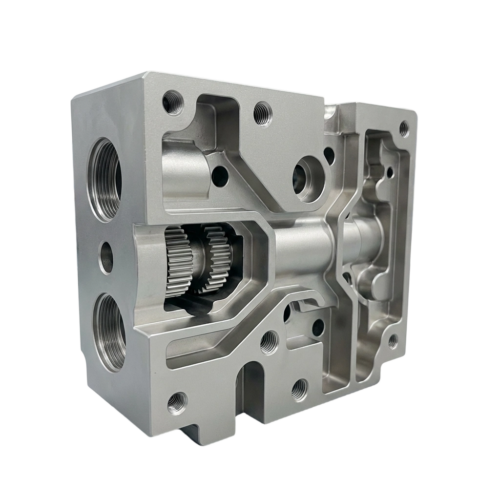

As machined surfaces reflect the condition of a part immediately after CNC processing. Edges are cleaned and burrs removed, while machining marks remain visible. This finish is often chosen when dimensional accuracy and cost efficiency are prioritized over surface appearance.

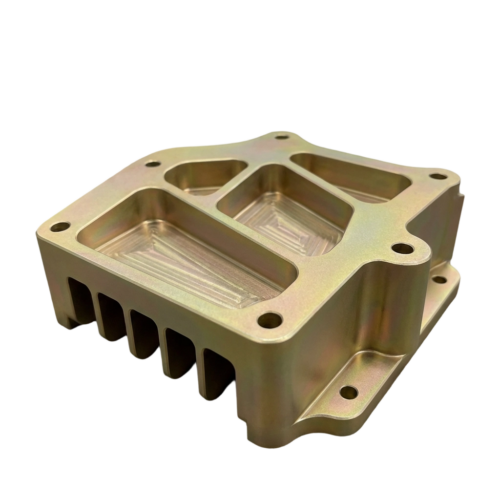

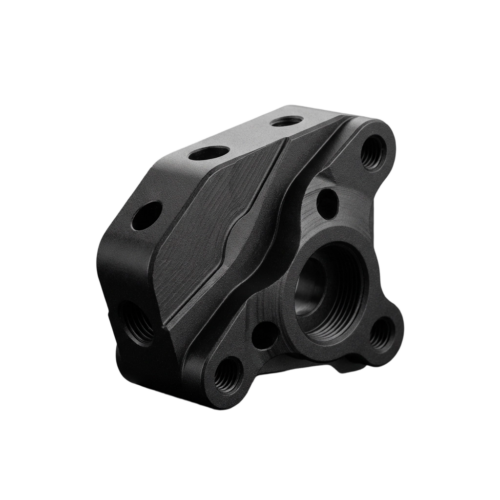

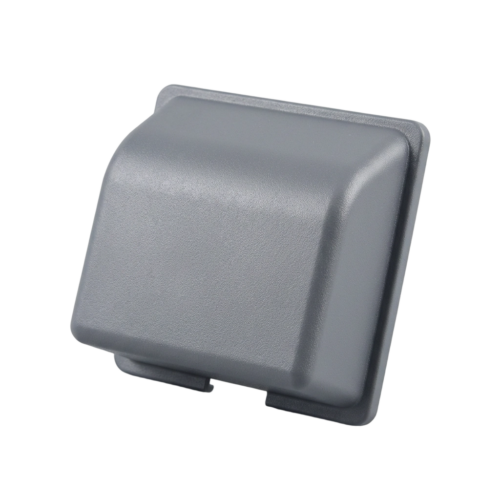

Powder coating forms a durable surface layer by curing dry powder onto the part. The finish offers strong resistance to wear and environmental exposure while supporting a wide range of surface textures.

Below are common questions about surface finishing and how different finishing options are selected and applied in CNC manufacturing.